Advantages of our EVOLUMIX trailed mixer

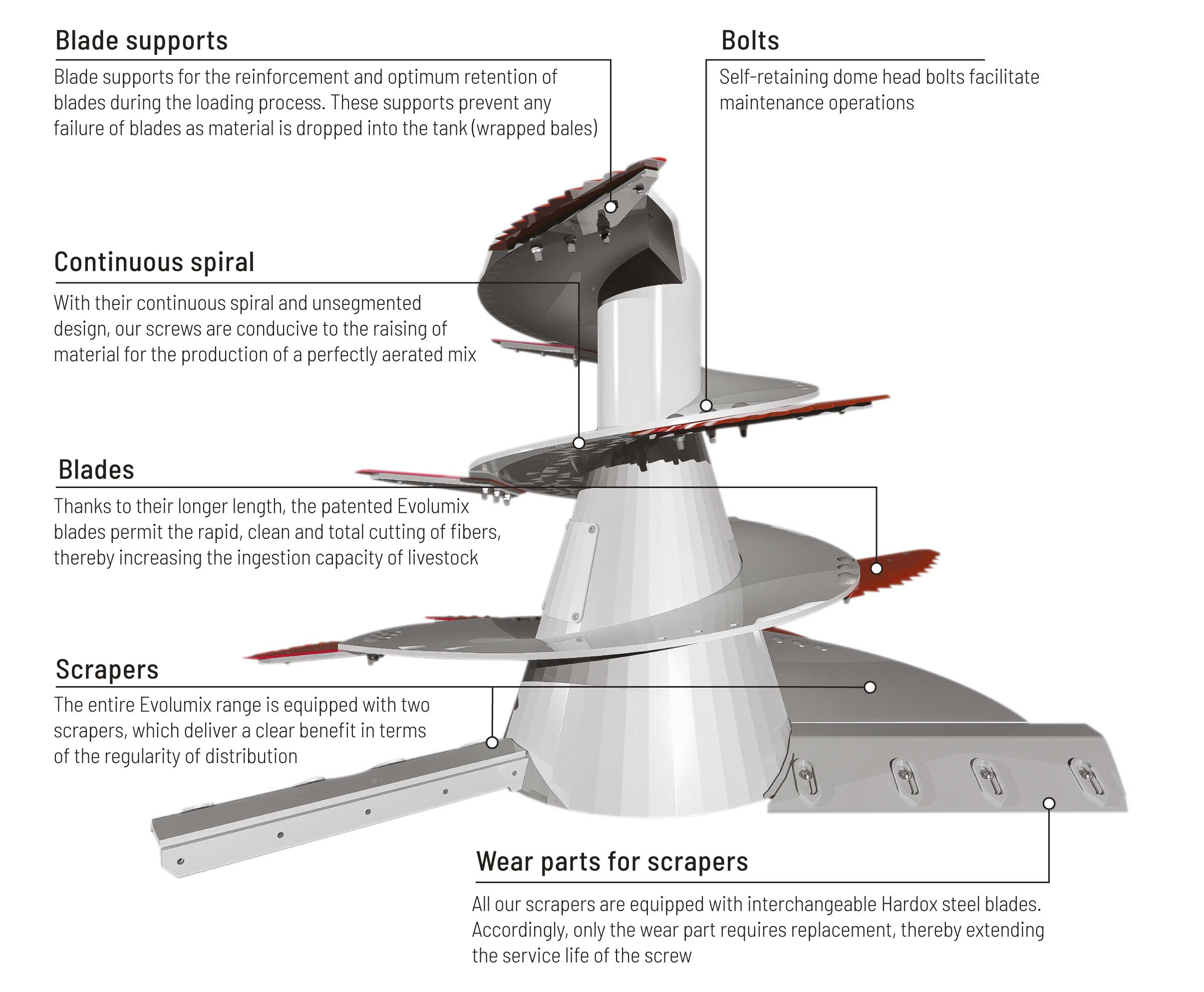

In pursuit of an optimum mix and the reduction of motive energy, our Hardox steel screws have been the subject of detailed analysis with regard to their design and available features. By a comprehensive design analysis of the shape of the tank and its screw, the Evolumix range delivers a mixing performance and an operating speed of exceptional quality, in a design which is also conducive to economies.

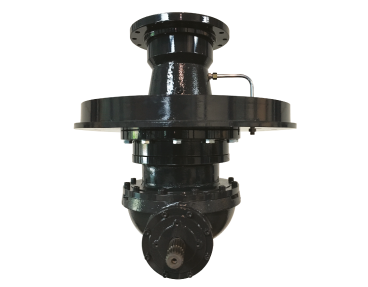

Oil-immersed reduction gear

Gearbox completely immersed in an oil bath, with reservoir and dipstick for easy access, eliminating the need for regular lubrication maintenance.

The gearbox is secured to the tank by a double plate to prevent any deformation.

Tubular overflow prevention ring

To prevent material from overflowing, all EVOLUMIX 1 screw tanks are fitted with an overflow protection ring welded to the tank. This type of ring prevents the material from sticking, as with traditional rings, and provides superior rigidity to the upper part of the tank.

Height-adjustable drawbar

To keep your mixer always level, whatever the tractor model, all our EVOLUMIX mixers have a drawbar whose height can be adjusted in 50 mm steps.

Independent C-section frame

The EVOLUMIX chassis has undergone advanced research to obtain the best attributes in terms of strength. Thanks to a C-profile design and the choice of high-strength steel, the chassis offers the perfect compromise between strength and flexion.

The C-profile frame offers greater ventilation than a closed frame, so there are no areas of permanent humidity. All our frames are fully protected by a high-quality paint finish.

8 and 20 mm thick steel bowl

The robustness and longevity of our machines has always been part of our brand DNA. Evolumix tanks are no exception to this rule, with 8mm-thick S355 steel walls and 20mm-thick tank bottoms. These thicknesses enable your mixer to work intensively for many years.

Reinforced tank base

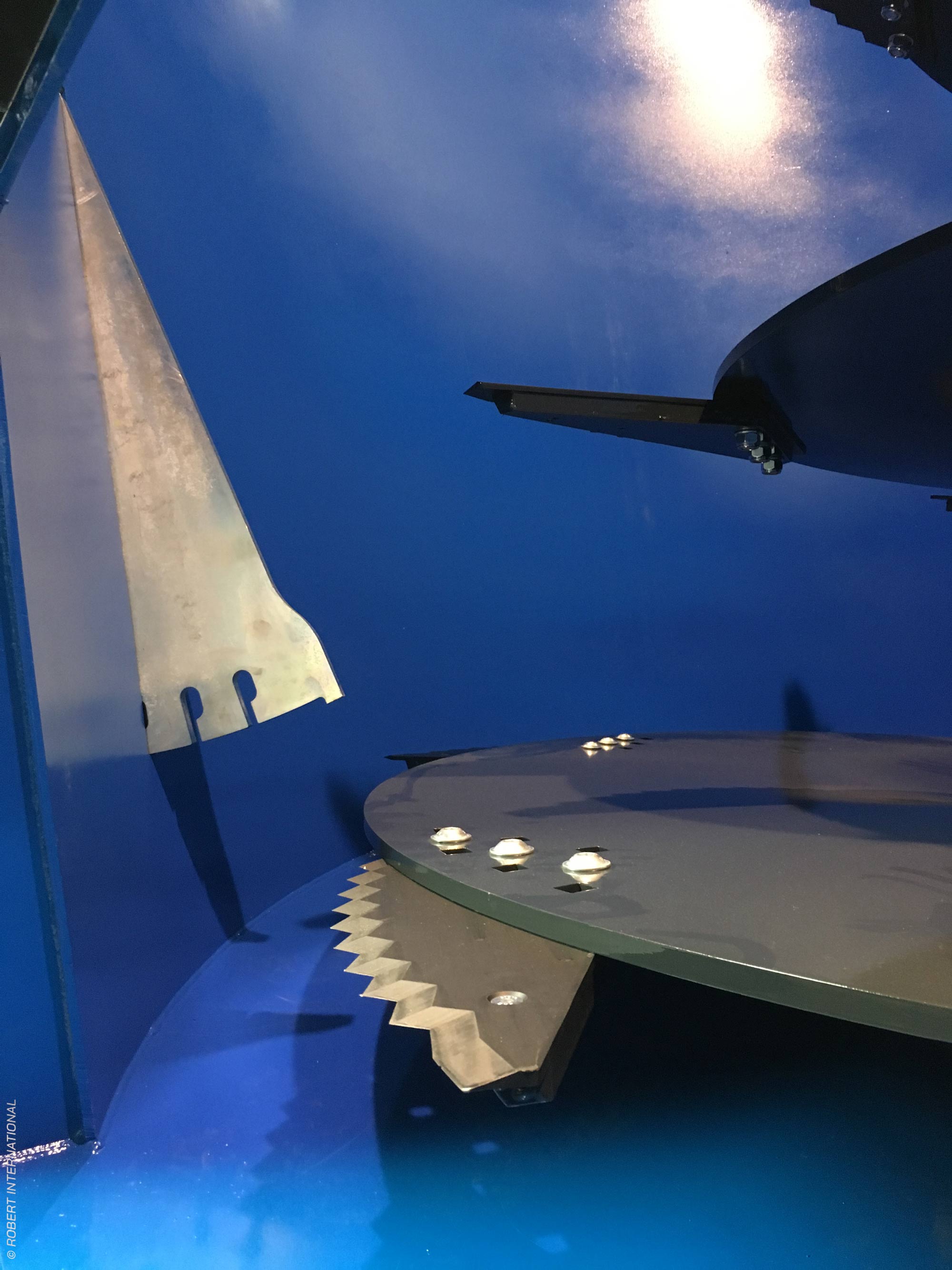

4 manual counter-blades

All our EVOLUMIX 2 screws are fitted as standard with 4 manual counter-rolls. These prevent the material from turning around the screw. Acting as a brake, the counter-knives hold back the material, which is then cut by the screw cutter.

Our counter-knives have 4 levels of depth adjustment, allowing the material to be cut to a greater or lesser degree.

4 load cells with programmable weighing

Bumper with inset lights

To protect your EVOLUMIX from collisions, our mixers are fitted as standard with a painted steel bumper with recessed lights.

Axle # 100 with wheels of 445 / 45 19.5 new tyres

To support heavy loads and provide maximum safety for the user, all EVOLUMIX models are equipped with a heavy-duty axle and new tires (not retreaded).

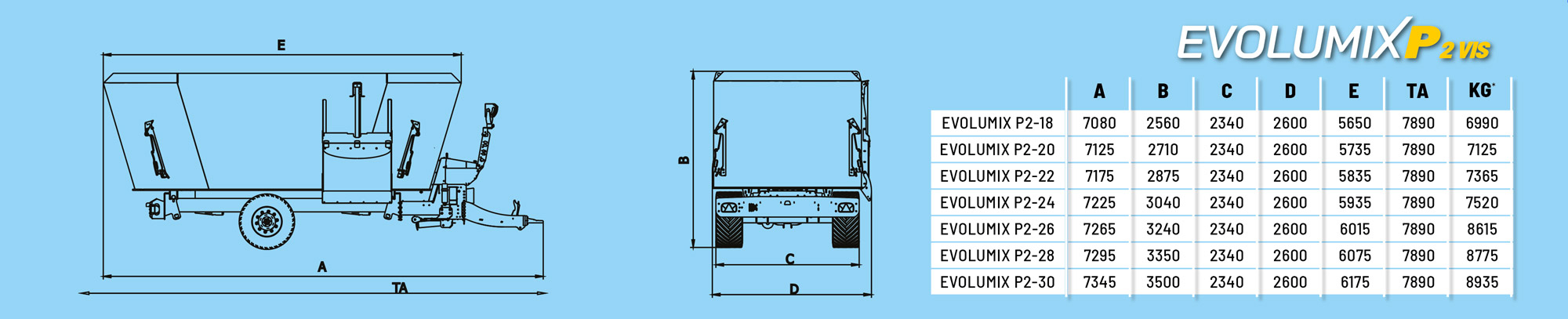

Standard equipment of the EVOLUMIX 2P mixer

Standard mixer devices with 2 vertical screws

Hardox steel screw

Tank of 8 mm and 20 mm gauge s 355 steel

Plated overflow prevention ring

Reinforced tank base

Independent C-section frame

4 manual counter-blades

PG 1602 worm gear reducer (torque of 15,700 Nm)

2-speed 150 HP main gearbox with manual control. Screw speeds of 17 and 34 r.p.m.

Distribution via left- or right-side lateral door with fixed plate

4 weight indicators with a diameter of 54 with programmable weighing (15 rations 15 ingredients)

Direct connection of hydraulic functions to tractor (2 x dual effect)

Inspection ladder

Height-adjustable drawbar with 50 diameter bolted ring

Béquille hydraulique avec pompe manuelle

Manual and hydraulic brake

Axle # 100 with wheels of 445 / 45 19.5 new tyres

Bumper with inset lights

Wide-angle cardan joint

Features