The advantages of the ROBERT beet chopper cleaner Model HB

Enjoy all the benefits of beet with our chopping and distributing unit.

At the turn of the century, fodder beet enjoyed a significant upsurge in Europe, as it formed part of the basic winter feed for cattle. However, this was not a preferred crop, as harvesting and distribution were not mechanized at that time, and required considerable manpower. Mechanical developments now permit the full exploitation of the advantages of fodder beet, which only provides nutritional benefits if administered in a reasonable dose.

Fodder beet is a highly palatable and energy-rich feed.

The nutritional benefits of beet are acknowledged. Considered as a concentrate rather than a feed, this rapidly fermentable source of energy increases the fat content rating, and delivers a very good return at a highly competitive cost.

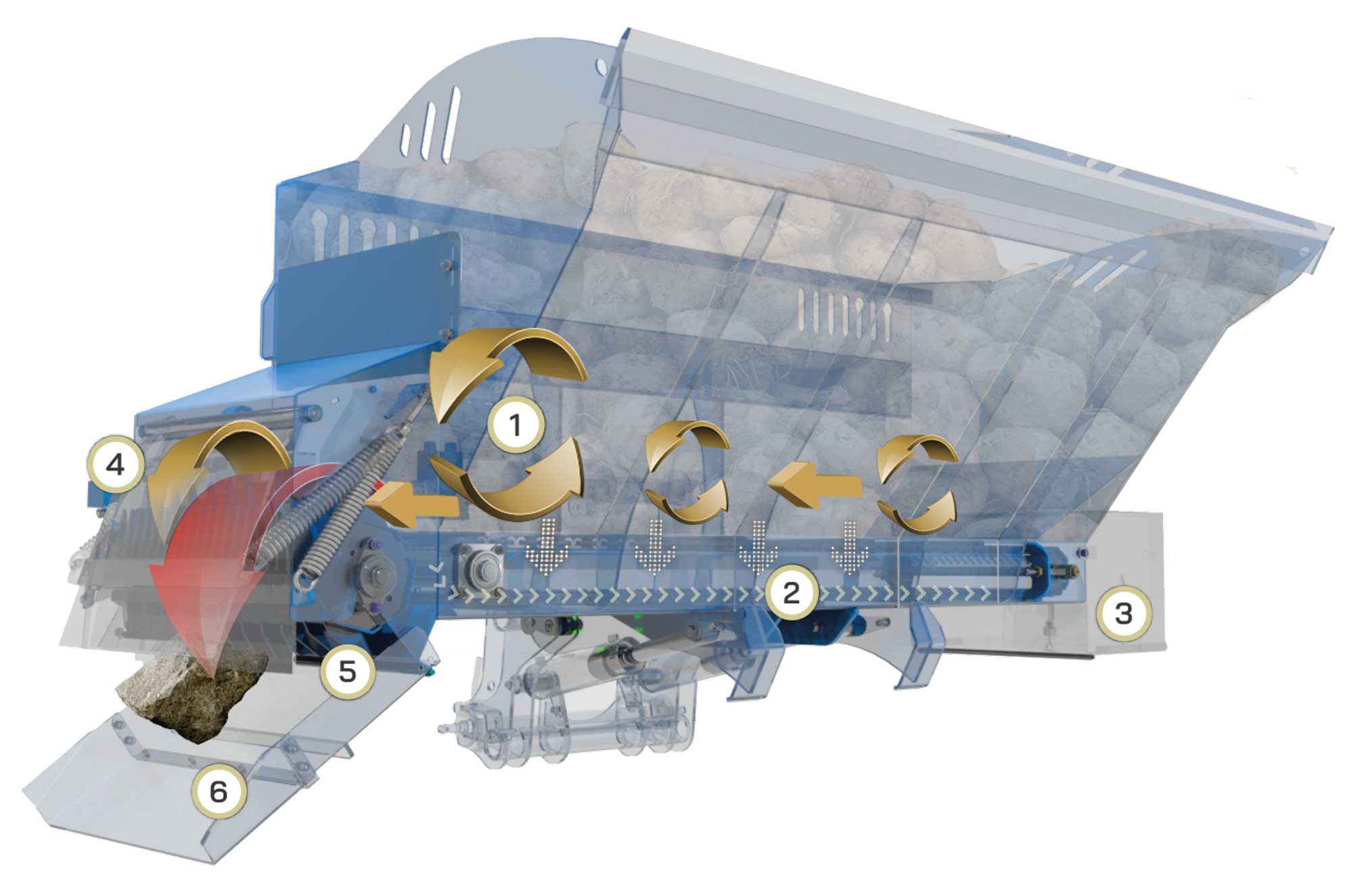

Hinge-mounted plate held in place by powerful springs, executing the function of counter-blades.

Feeding plate with hydraulic opening for the accurate distribution of product.

Cleated conveyor with sieve floor.

Crushing rotor equipped with 32 special spikes.

Adjustable hatch for the control of product, according to the size of beets and other crops.

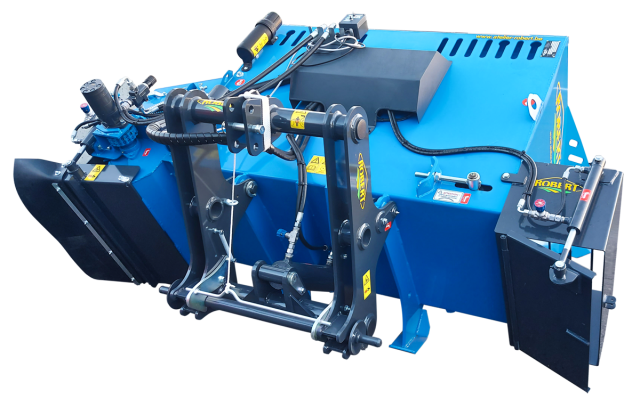

Frame with 3-point support mounting for the hydraulic tipping of the box (3-point tractor range).

Hardox steel loading blade.

- High resistance box.

- Cleated conveyor with independent gear motor drive from the crushing rotor, with rotational speed control.

- Left- or right-side distribution.

- Crushing rotor with high-powered hydraulic motor drive.

- Bolted tow bar for hitching to all types of telescopic handlers and other facilities.

- Solenoid valve control of functions.

- Conveyor tension control arranged on the exterior of the body for fast and easy access.

- Reinforced frame for the prevention of any distortion of the body. Designed for intensive and long-term use.

- Soil recovery container with emptying hatch.

A unique and efficient system for chopping, distributing and cleaning all types of beets and other feed.

Beet has long been excluded from cattle feed on the grounds of the cost of distribution. Cleaning and de-stoning processes were not mechanized, and required substantial manpower. The HB model produced by ROBERT addresses and overcomes this issue with a complete and innovative 5-in-1 system.

- Cleaning: The flat chain conveyor advances towards the rotor, with the resulting agitation of beets. By the combination of the specific shape of the container and the controlled movement of the flat chain conveyor, a motion of beets is initiated which is conducive to the removal of any residual soil.

- Soil removal: The container of the beet chopping unit features a sieve floor, which allows soil to pass into a double bottom. The chain conveyor, driven by a powerful high-capacity variable-speed gear motor, immediately removes any soil which falls into the double bottom to the soil container which is fitted to the side of the machine.

- Soil recovery: Soil is collected in a soil recovery container which is arranged on the opposite side to the cutting system. The upper part of the container is open, in order to permit the easy inspection of level. The container is emptied manually, or by means of a hydraulic cylinder (as an option) via the opening of the hinge-mounted emptying hatch.

- Chopping: The beet crushing rotor is driven by a high-powered hydraulic motor. Crushing is executed by the crushing rotor, equipped with special blades which engage with hinge-mounted counter-blades which are held in place by powerful springs.

- Distribution: The actuator-controlled distributor plate permits the accurate distribution of kibbled beets at the desired location.

- Safe de-stoning: The crushing rotor is equipped with blades which have been specially designed to permit the passage of stones without damaging the rotor. The counter-blades are hinge-mounted and held in place by powerful springs. These open automatically in order to permit the removal of stones with no damage to the rotor.

Standard equipment

- High-resistance box

- Tripping body

- Removable soil recovery container

- Conveyor with 80/12 flat chains and full steel 40x20 board

- Conveyor driven by a variable-speed gear motor

- Foreign body safety feature with counter-blades

- Hydraulic kibbler

- Left / right option distribution (HB...T models only)

- Right / left option distribution (HB... models only)

- Independently controlled distribution door

- Sieve floor

- Solenoid valve control (HB...T models only)

- Solenoid valve control with control box (HB... models only)

- High-power hydraulic motors (HB...T models only)

- Automatic coupling

- Bolted coupling (HB...T models only)

- 3-point linkage (HB models only)

- Anti-corrosion treatment: epoxy primer and polyurethane finish

- Hitch included (type to be specified)

Features