The benefits of the new HYDROPAIL 1 mini straw blower

The HYDROPAIL 1 GLC has been developed to meet many of the criteria and requirements of farmers with small, low-powered front-mounted machines:

Reliability

Meticulous design and the use of high-quality hydraulic and mechanical components from globally renowned and recognized manufacturers elevate HYDROPAIL 1 straw blowers to the level of the most reliable machines available on the market.

Ease of maintenance

HYDROPAIL 1 straw blowers are designed for easy maintenance, due to the exceptional ease of access to conveyor belt tensioners and mechanical components. The turbine is equipped with an access hatch for the execution of all the necessary checks for its correct operation.

Exemplary robustness

Our reputation has been forged over the years by the exemplary quality and robustness of our machines. The HYDROPAIL 1 is no exception to this rule, due to its non-deformable one-piece shell.

Control of flows

The HYDROPAIL 1 incorporates all the benefits derived from many years of research in our design office into the behaviour of air and material flows. By the impeccable control of these flows, we are able to market one of the best straw blowing systems available on the market.

High capacity

Our super-powerful separators have undergone extensive tests in order to ensure that they meet the capacity requirements of stock farmers. By the combination of the separator with a high-efficiency turbine, the capacity of the HYDROPAIL 1 straw blower is among the highest available on the market.

Visibility

Due to its front-mounted position, which ensures the excellent visibility of manoeuvres, the HYDROPAIL 2 can reach the tightest spaces. Particular attention has been paid to ergonomics in the design of the HYDROPAIL 1, in order to provide the user with excellent visibility during straw blowing operations, whilst maintaining an unobstructed view of the environment in which they are moving.

The details that make all the difference.

1 • Reinforced one-piece shell

A welded and reinforced one-piece shell suitable for all formats of round and square bales. The specific design of the HYDROPAIL 1 permits the execution of clean working.

2 • Straightforward adjustment of conveyor belt tension

For the adjustment of conveyor tension, tensioners are arranged on the exterior of the shell. As a result, this operation is both quicker and easier.

3 • High-capacity gearbox

The conveyor drive incorporates a high-capacity variable-speed gearbox.

4 • A powerful separator motor

A high-power separator motor permits the efficient separation of any type of bale.

5 • Electrical control unit

The electrical control unit permits the individual control of every element of your straw blower from your cabin.

6 • High-torque hydraulic motor

The turbine is rotated by a powerful high-torque hydraulic motor, which is specially designed for the low pressures and the oil capacity delivered by handling trucks.

7 • Bolted hitch gear

Our coupling hooks are detachable, in the event of any replacement of the model of handling truck used.

8 • Reinforced feed conveyor

A conveyor comprising 80/12 flat chains and 60 x 30 mm welded slats for the efficient delivery of bales to the separator.

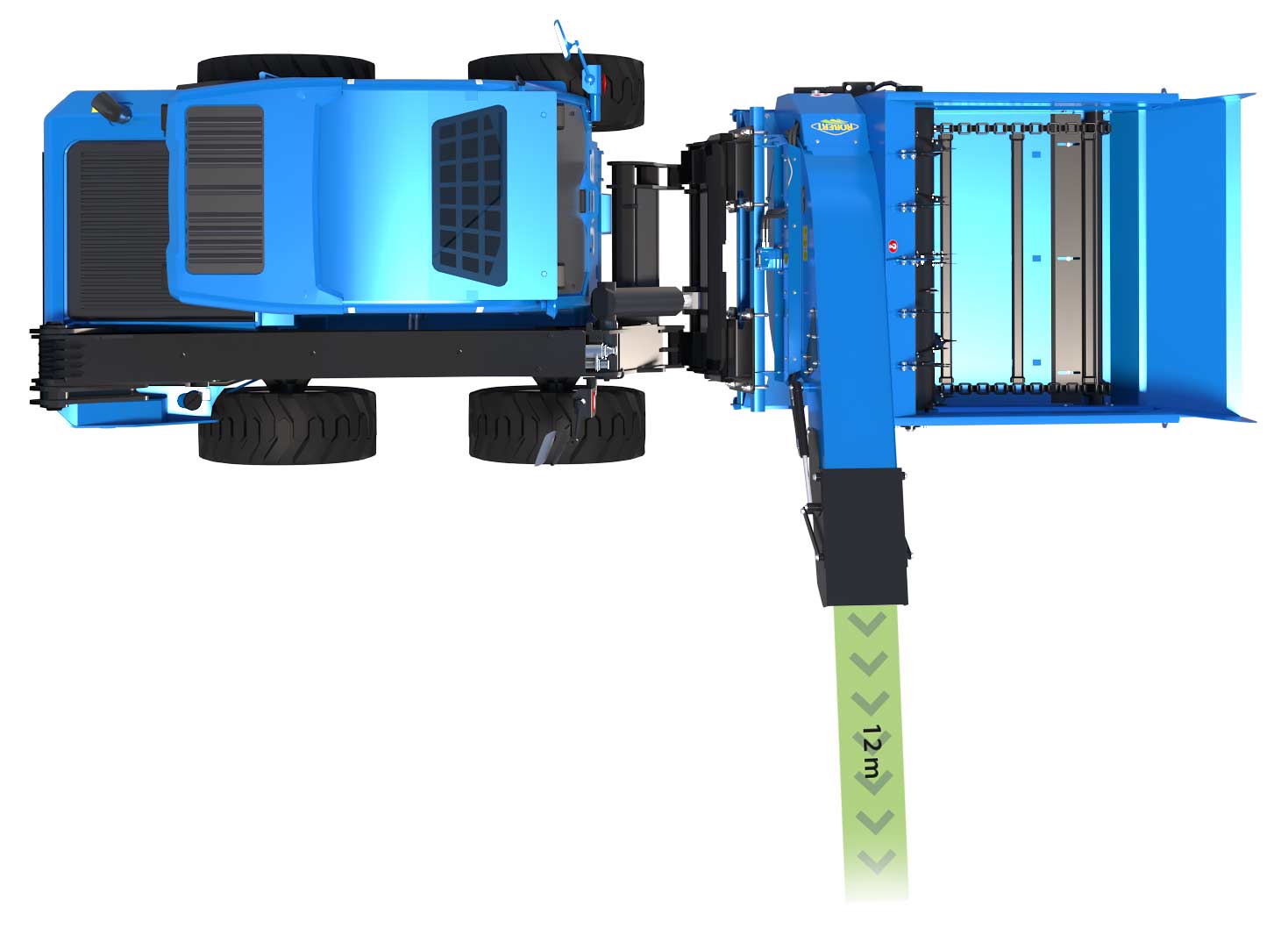

A lateral chute for high-precision, long-distance straw blowing

Ideal for spaces with limited height, the lateral chute of the HYDROPAIL 1 delivers a breath-taking performance, in terms of straw blowing distance, with a reduced footprint.

Depending upon climatic conditions and the quality of straw, it is possible to achieve straw blowing distances of up to 12 metres, while maintaining a substantial flow rate.

CombiA combination of refined technical features for the achievement of optimum straw blowing.

The innovation behind every bale: we've created the first telescopic front straw blower.

All technical features were analyzed, studied and tested to an advanced level before the start of production. Since its creation in 1998, the HYDROPAIL has undergone numerous technical improvements on all its essential components, making it the most advanced front-mounted straw blower on the market.

1 • Jet concentrator chute

In order to achieve a consistent straw blowing capacity at a specific location, it is important that the quantity of straw deposited should be clearly visible. In order to prevent any umbrella-shaped jet, the lateral and rotating chutes of the HYDROPAIL 1 feature a geometry which has been specially designed to concentrate the straw into a powerful and compact jet. This improves the visibility of work executed, whilst producing a substantial reduction in the quantity of dust in suspension in the air.

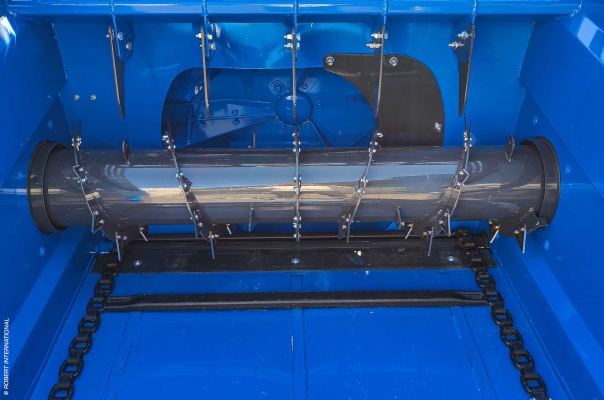

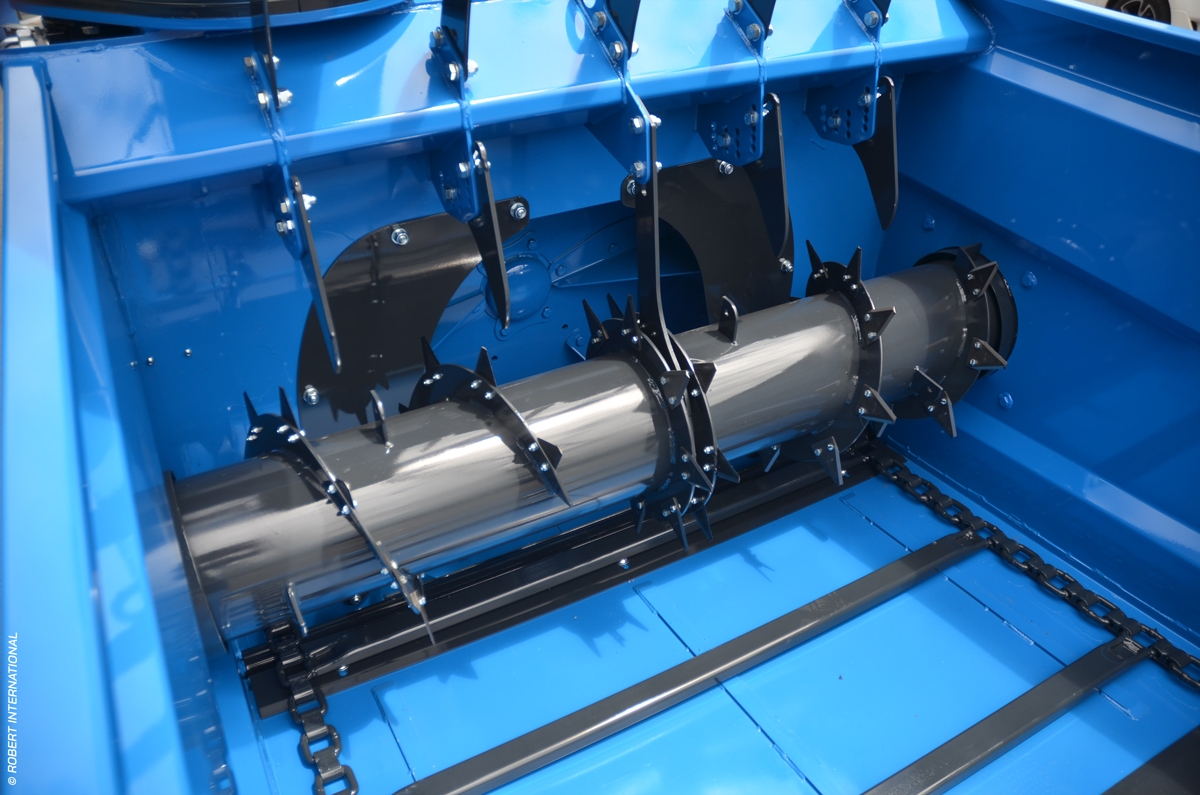

2 • Spiral separators

For the execution of powerful separation, while generating a movement of straw which is conducive to its intake into the turbine, our hydraulically-driven separators feature a spiral design, and generate dynamic conditions which increase the quantity of straw delivered to the turbine. This particular design has proved its effectiveness for both round and square bales.

3 • Regulator combs

As it is not possible to maintain a consistent quality of straw, the HYDROPAIL 1 has been designed for the full preservation of straw characteristics. The regulator combs permit the execution of the necessary adjustments.

4 • Controlled air intake

In order to achieve effective straw blowing, it must be possible to control the quantity and movement of air and straw in the turbine and the chute. Particular attention has been paid to this point, in order to achieve an exceptional result.

5 • Twin-flux turbine

The HYDROPAIL 1 features a special and exceptionally quiet twin-flux ROBERT turbine of diameter 1 metre, with 6 bolted blades for maximum straw blowing efficiency.

Standard equipment Mini straw blower HYDROPAIL 1 GLC

- Conveyor driven by a variable-speed gear motor (manual variable drive control)

Conveyor with flat 80/9 chains and 60x30 boards

1 hydraulic bale separator

Regulating grabs

1.6m bolted blade turbine

Hydraulically driven turbine

Lateral chute on the right - for GL or GLC models

Double bottom seal

Electric control hydraulic distributors

Electric control cabinet box (with harness and electric outlets)

Removable coupling hooks

Anti-corrosion treatment: epoxy primer and polyurethane finish

Hitch gear included (type to be specified)

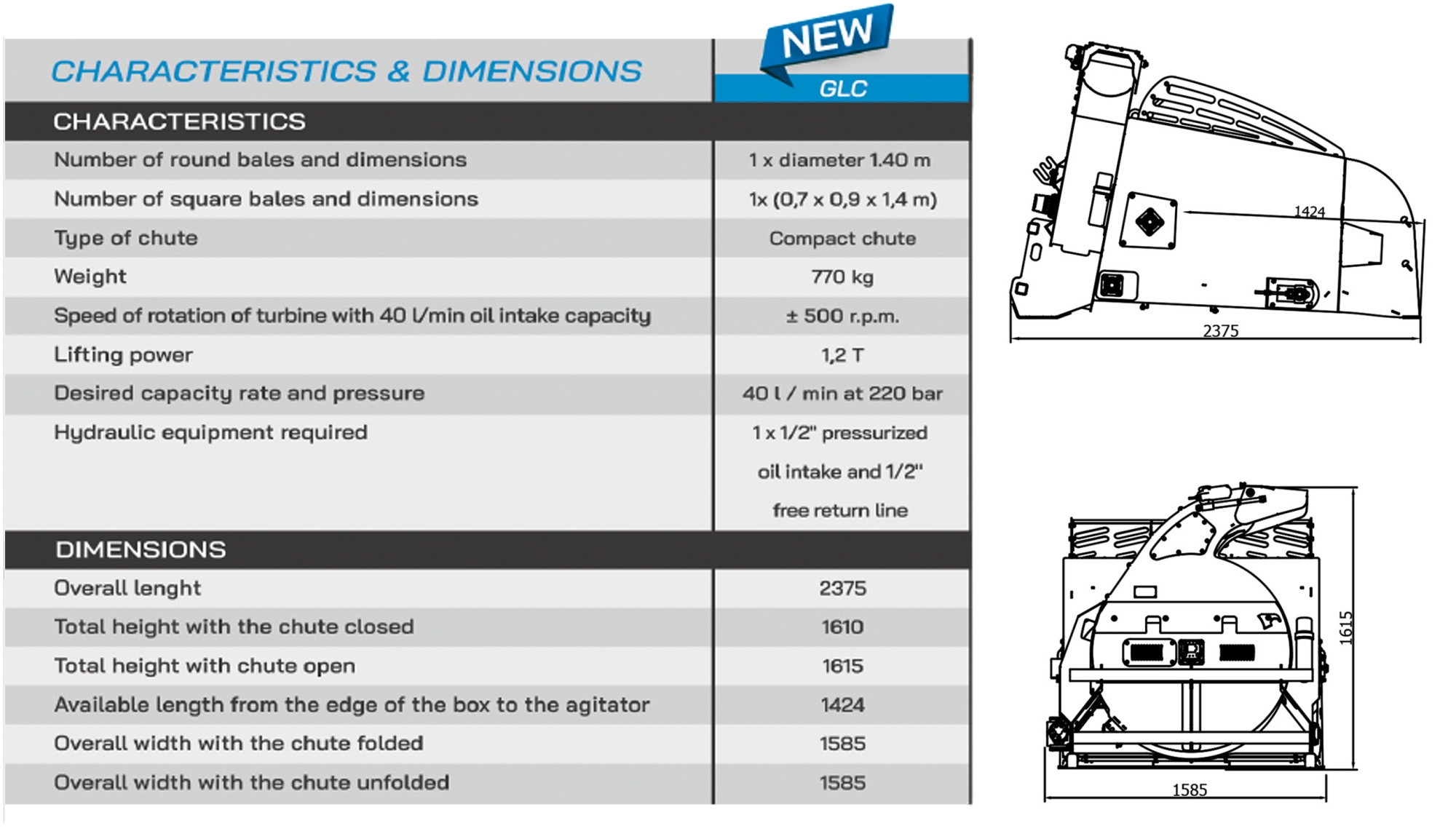

Features of the HYDROPAIL 1 GLC mini straw blower