The advantages of the GDB7200 shredding unit

A high quality of cut, even over large widths

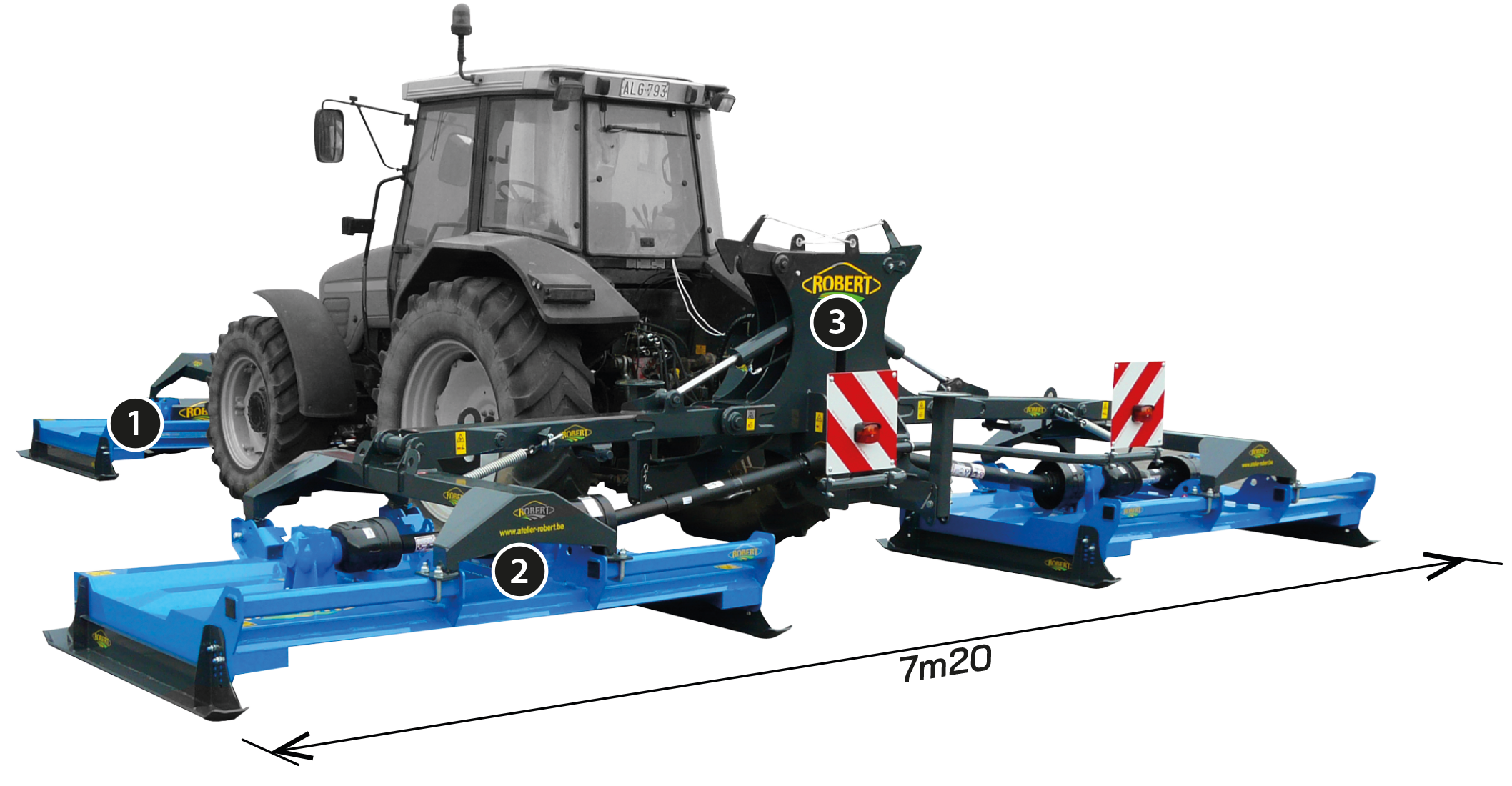

The GDB7200 is a shredder unit with a working width of 7.20 m, equipped with a front-mounted 2.80 m mower and two independent rear-mounted 2.40 m mowers, arranged on a central frame.

Conceived in the interests of durability, performance and quality of cut, the GDB7200 is distinguished by its advanced design, robust manufacture and the employment of high-quality components. Thanks to its numerous technical advantages, the GDB 7200 shredder unit is distinguished by ease of operation and optimum results, even on uneven ground. Its cutters generate a suction action, raising grass and waste materials, which are then finely shredded and converted into fertilizer.

1 • Front mower

The mower located at the front of the unit allows mowing over a width of 280cm. The grass is cut and shredded before the tractor wheels pass over it, giving a perfect and uniform result.

2 • Perfect fit

Thanks to its three mowing zones and 6 rotors, the GDB7200 shredding unit ensures a perfect and regular cut even on uneven terrain over a width of 7m20.

3 • Pendulum system

The mowing unit is equipped with a pendulum system that allows each unit of the unit to follow the terrain independently and with precision.

4 • High quality

Each unit of the mowing unit is made of high quality steel S355. The steel profile frame is treated with an anti-corrosion primer and a polyurethane paint finish. This makes it easy to clean and maintain and ensures that the mower unit will work for many years in good condition.

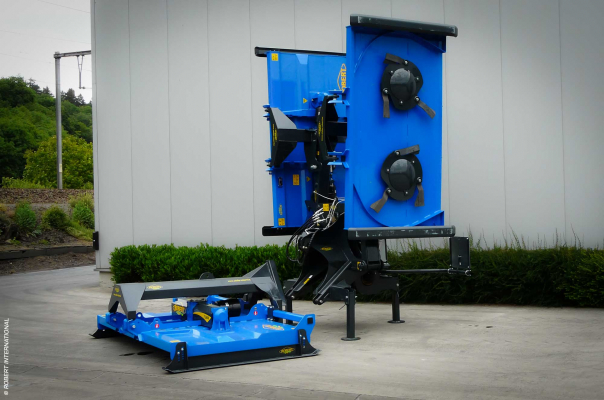

5 • High power enclosures

On the front part, the transmission is carried out via a central power take-off box with a power of 130 hp at 1000 rpm connected by chain couplings to two other boxes with a power of 70 hp. On the rear part, the transmission is also carried out via a central power take-off box of a power of 130 hp at 1000 rpm and sent by cardan shafts with friction clutch to four other boxes of 70 hp. These two boxes redistribute the transmission via two cardan shafts with friction clutch to two other 70 hp boxes located on the extensions. These gimbals allow a complete folding of the extensions.

6 • Security

Extensions fold down for a small footprint during transport. A safety locking system prevents the extensions from unfolding without the user's intervention.

7 • Ease of use

To avoid loss of time and gain comfort when changing direction of mowing, the rear lift system is equipped with double rod cylinders offering two closing positions.

Standard equipment

- Numbers of rotor in the front: 2

- Numbers of rotor in the rear: 4

- Number of knives in the front 6

- Number of knives in the rear: 12

- Circular knife holders

- Ventilated and retractable,

- Cutting height adjustable from 4 to 18 cm with spacers

- 1 independent box per rotor

- Power take off gearboxes 1000 rpm: 180hp - angular drive: 75hp

- Slip clutch and freewheel

- Gearbox power: primer box 1000 rpm: 180 hp- angular drive: 75hp

- Anti-corrosion treatment: epoxy primer and polyurethane finish

- Road signaling kit

Features