Its advantages

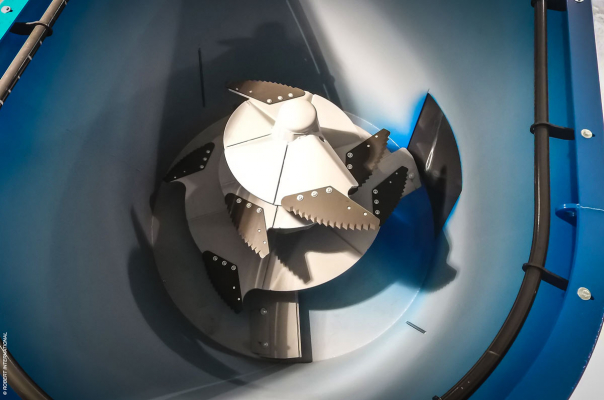

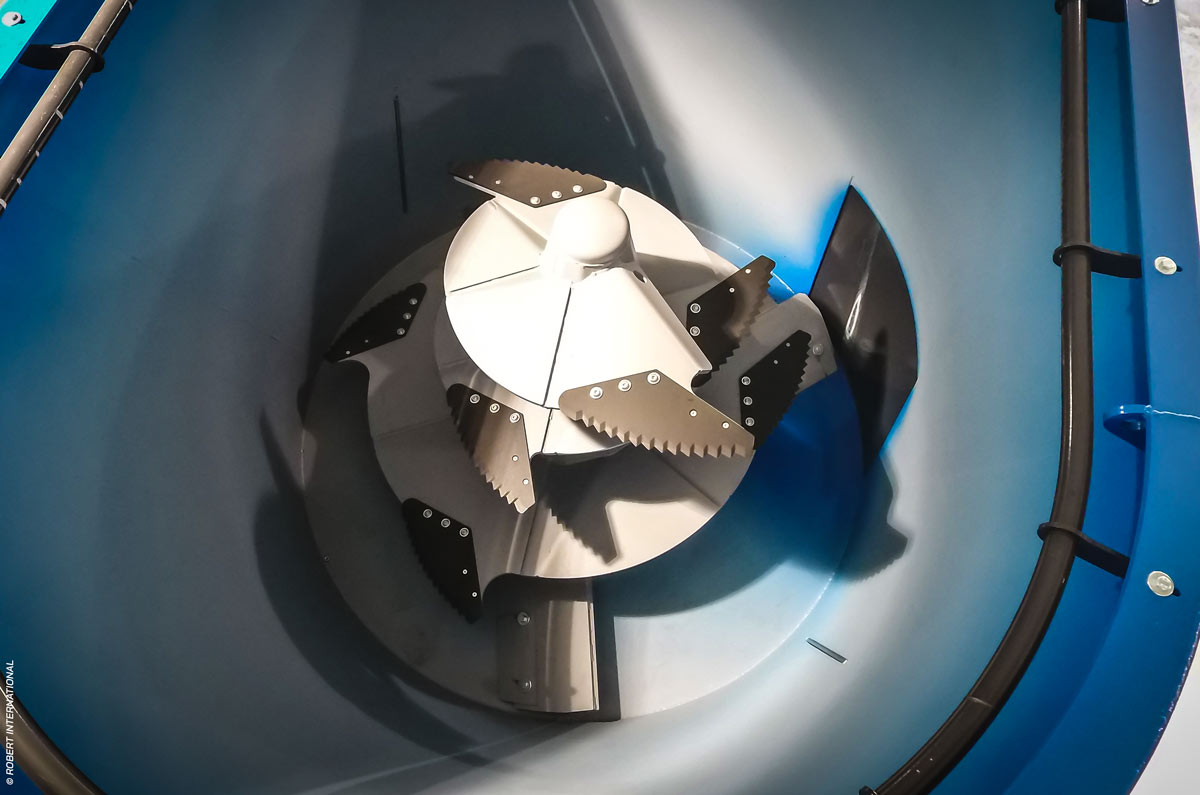

Removable counter-cutters

Fitted as standard on all MASTERMIX models, counter-cutters ensure the optimum cutting of long forage. Their position in the tank and shape have been designed to deliver maximum efficiency, combined with optimum ergonomics.

Tank-integrated frame

Rigidity and solidity delivered by a 15 mm steel frame welded directly to the tank, ensuring the rigidity of the tank structure

A cost-effective screw

Designed for cutting and mixing with the minimum motive power, the MASTERMIX screw constitutes a development in itself.

3-point high-precision weighing system

For the execution of accurate mixes, controlled by three ∅ 70 mm balances, with control screen.

Oil bath gearbox

Gearbox completely immersed in an oil bath with reservoir and easily accessible control gauge avoiding any regular maintenance at the lubrication level.

Standard equipment

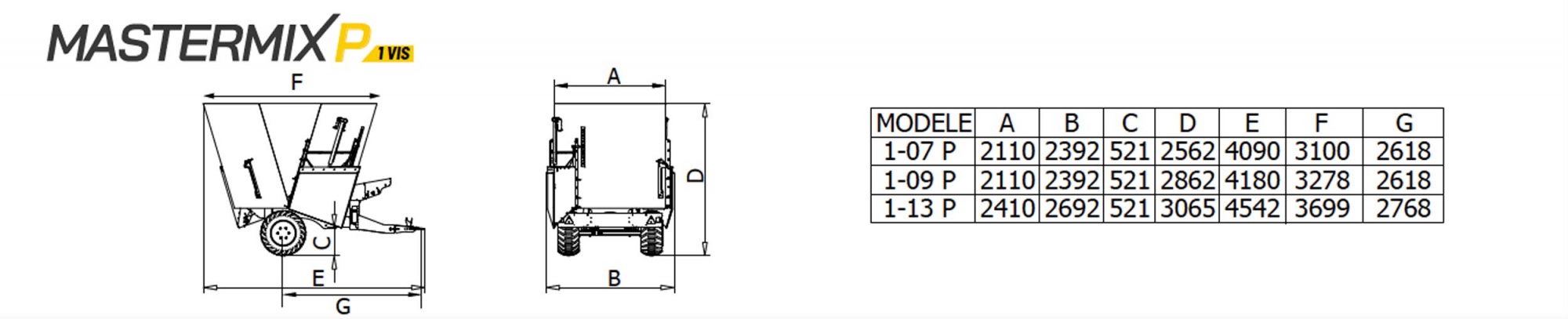

- Mixer with 1 vertical screw : MASTERMIX 1-7 to 9 : ø 2100 mm

- Mixer with 1 vertical screw : MASTERMIX 1-13 : ø 2400 mm

- 8 mm and 15 mm tank in s 355

- Tank-integrated frame

- 2 manual counter-cutters

- Worm gear reducer PG 1202 (torque 11600 Nm) - MASTERMIX 1-7 to 9

- Worm gear reducer PG 1602 (torque 15700 Nm) - MASTERMIX 1-13

- With no gearbox

- Speed of worm: 540 rpm / MASTERMIX 1- 7 to 9: 27 rpm

- Speed of worm: 540 rpm / MASTERMIX 1 -13: 25 rpm

- Distribution through a front right side door with fixed shelf

- 3-point weighing system with Ø 70 balances

- Non-programmable weighing system

- Direct connection of hydraulic functions to tractor.

- Inspection ladder

- Height adjustable drawbar

- Manually operated jack

- Manual and hydraulic brake

- Axle # 70 with wheels of 400 / 60 15.5 new tyres

Features