History and assets of the BT

Often imitated, but never equalled.

In 1977, Atelier ROBERT had the distinction of being among the first manufacturers to undertake the series production of belt feeder silage distributors.

Over a period of more than twenty years, and with the assistance of its clients, Robert has undertaken the continuous development of these products.

Since the 1990s, the use of telescopic jib-mounted implements on farms has become increasingly widespread. Atelier ROBERT has drawn on over twenty years of experience in the manufacture of belt feeder silage distributors to create a new model which is specially adapted to telescopic jibs.

At the same time, the BTL model was created in order to meet requirements for loader-mounted buckets. Today, BT and BTL buckets deliver the benefits of over 40 years of experience in the field – these are products of exemplary efficiency and robustness, which are recognized by all users.

Ses atouts

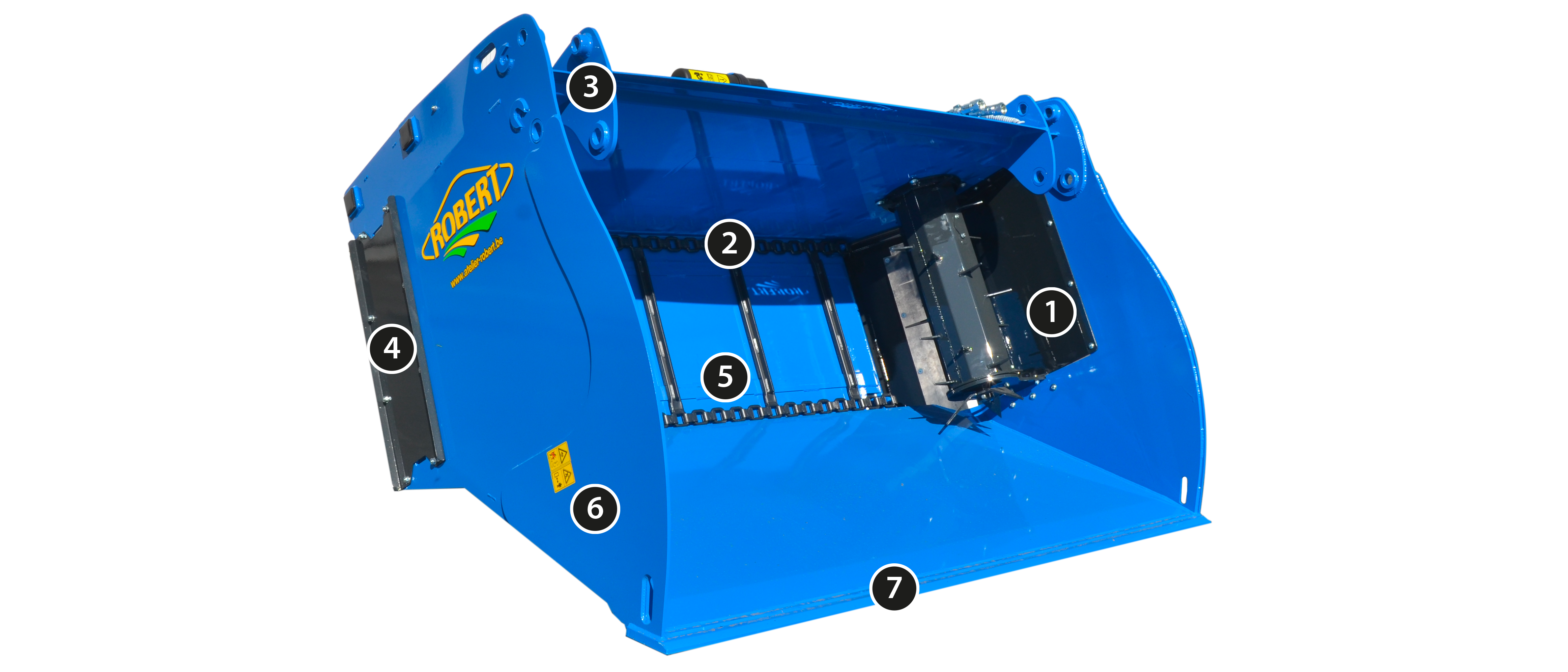

1 • Efficient distribution

Efficient distribution is achieved by means of the bale separator, which is designed for consistent unloading.

2 • Conveyor with 80/12 flat link chains and reinforced slats

In the interests of rapid and efficient distribution, our buckets are equipped with a 80/12 flat link chain conveyor with reinforced tubular slats.

3 • Preconfiguration of silage feeder options

All our buckets are produced to a standard design, in order to allow the subsequent addition of a silage feeder system option.

4 • Access hatch

In order to facilitate cleaning and servicing operations, our BT 1-output buckets are equipped with an access hatch as standard.

5 • Wear slats on the base

The steel wear skate prevents any premature wear of the base of the bucket

6 • Lateral reinforcements

Reinforcement plates are fitted to the side walls of the bucket, in order to minimize wear

7 • HARDOX steel wear blade

In order to permit long-term operation without damaging your bucket, the entire BT range is equipped, as standard, with a bevelled HARDOX steel wear blade and wear skates of thickness 20 mm and hardness 500 H.B.

8 • Variable conveyor speed

The conveyor is driven by an oil-immersed gearbox equipped with a variable speed hydraulic motor.

9 • Bale separator drive

The high-capacity separator motor permits the efficient separation of any type of silage.

10 • Position indicator

This permits the viewing of the correct position of the bucket during loading.

11 • Hydraulic plate

A hydraulic plate with independent solenoid valve-controlled opening ensures perfect leak-tightness during transport and permits an optimum offset during distribution.

12 • Double floor

This ensures the leak-tightness of the bucket during distribution.

13 • Reinforced bucket

In order to permit intensive long-term use, the bucket is equipped with reinforcements for the prevention of any strain.

14 • Bolted hitch gear

Bolted hitch gear permits the offset of the bucket, and facilitates a straightforward transfer to any type of carrier machine at a later date, with no necessity for modification.

15 • Conveyor tension

For the adjustment of the conveyor tension, the tensioner is arranged on the exterior of the body.

16 • High-grade steel

Bucket manufactured from high-grade S355 steel of 5 - 8 mm gauge.

Even greater multi-functional capability provided by various silage feeder options.

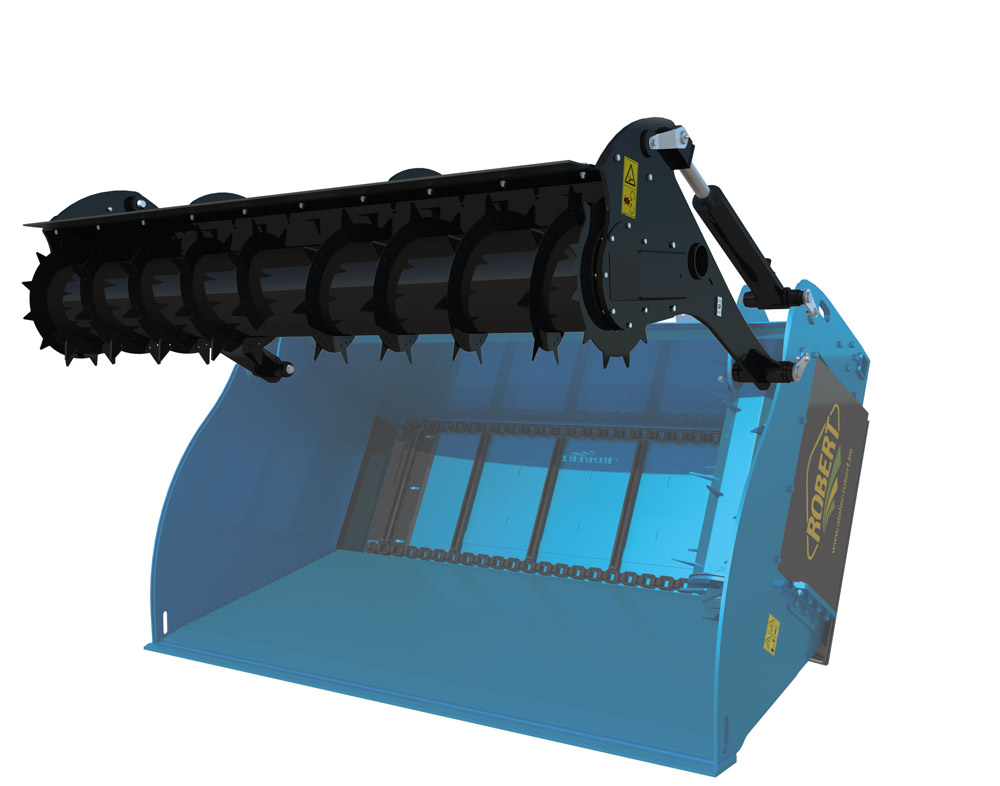

Articulated silage feeder rotor

According to width: +/- 574 kg Impeccable cutting face For BT & BTL

An impeccable cutting face is provided by the large diameter rotor, fitted with detachable blades arranged in a spiral pattern, mounted on two arms which are actuated by two actuators, with automatic lowering control.

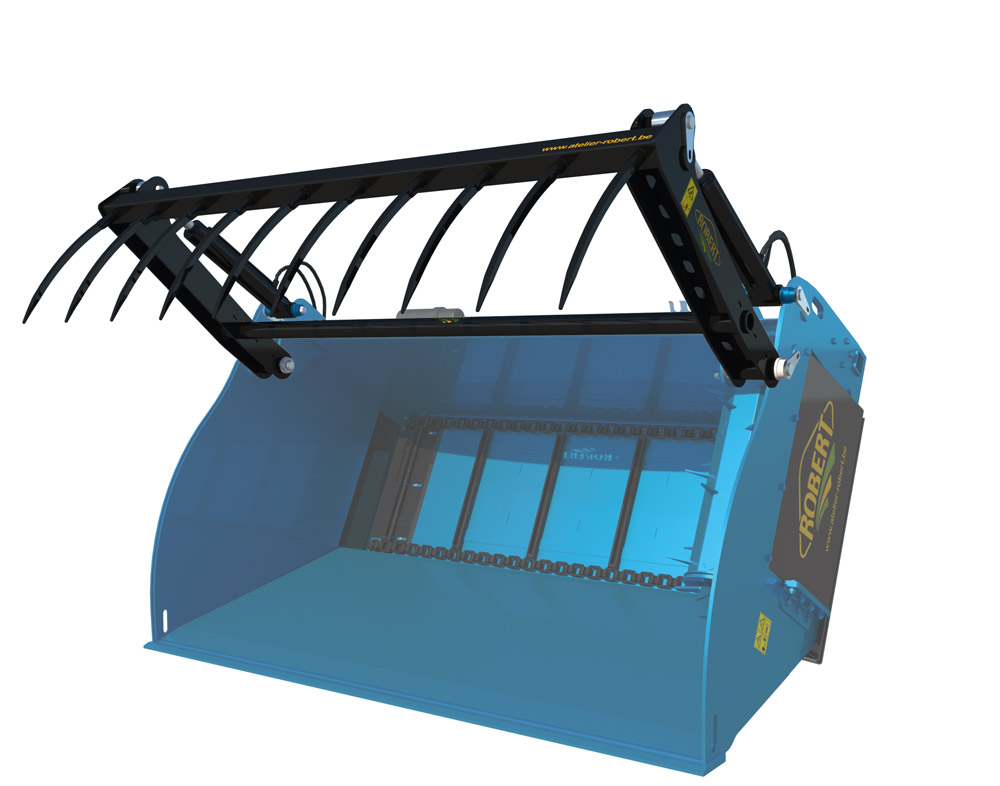

Articulated arm and gripper

According to width: +/- 373 kg A clean cutting face For BT & BTL

Greater flexibility delivered by the double-articulated arm and gripper with four actuators; this permits operation in an outthrust position, out of reach of silage stores; speed of operation is combined with cleanliness and an impeccable silage cutting face.

Crocodile-type silage feeder jaw

According to width: +/- 200 kg Multi-functional capability For BT & BTL

The simplicity of this jaw permits silage feeding and the handling of straw bales or other baled.This jaw is equipped with detachable forged teeth and two actuators arranged on the exterior of the bucket, avoiding any contact with silage stores.

Silo Cut cutting jaw

According to width: +/- 574 kg Multi-functional capability For BT

High-speed and impeccable cutting of silage delivered by a gate which is fitted with detachable blades and actuated by two powerful actuators, arranged on the exterior of the bucket.

Standard equipment

- High-resistance box

- Conveyor with flat 80/12 chains and reinforced tubular stats

- Conveyor driven by a variable-speed gear motor

- Hydraulic beater with unrolling chain guard

- Independently controlled hydraulic unloading flap

- Left side distribution / right side as an option

- Wear blade 150 x 20 Hardox

- Removable coupling hooks

- Anti-corrosion treatment: epoxy primer and polyurethane finish

- Hitch included (type to be specified)

Features