Its advantages

An essential machine for your farm.

Over the years, thanks to their highly robust design and their operational versatility, ROBERT silage distributing buckets have become a benchmark on the European market. With an extensive range of models and a wide variety of options available, this has become an essential machine for the straightforward, high-speed and low-cost feeding of your livestock.

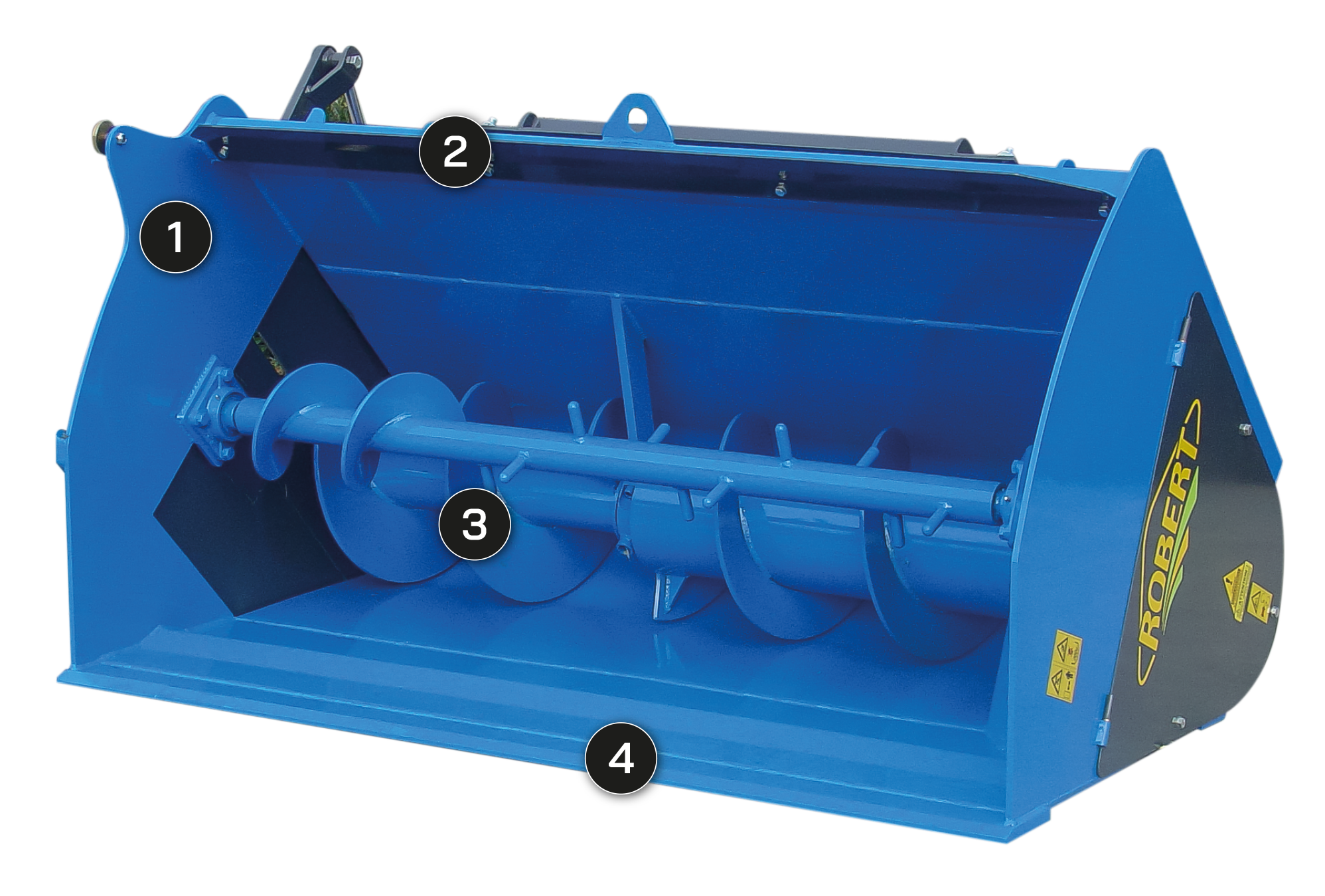

1 • High-grade steel

Bucket manufactured from high-grade S355 steel of 8 and 10 mm gauge.

2 • Overflow prevention plate

In order to ensure clean and efficient transport, all buckets in the BV range are fitted with an upper overflow prevention plate, to prevent any loss of product.

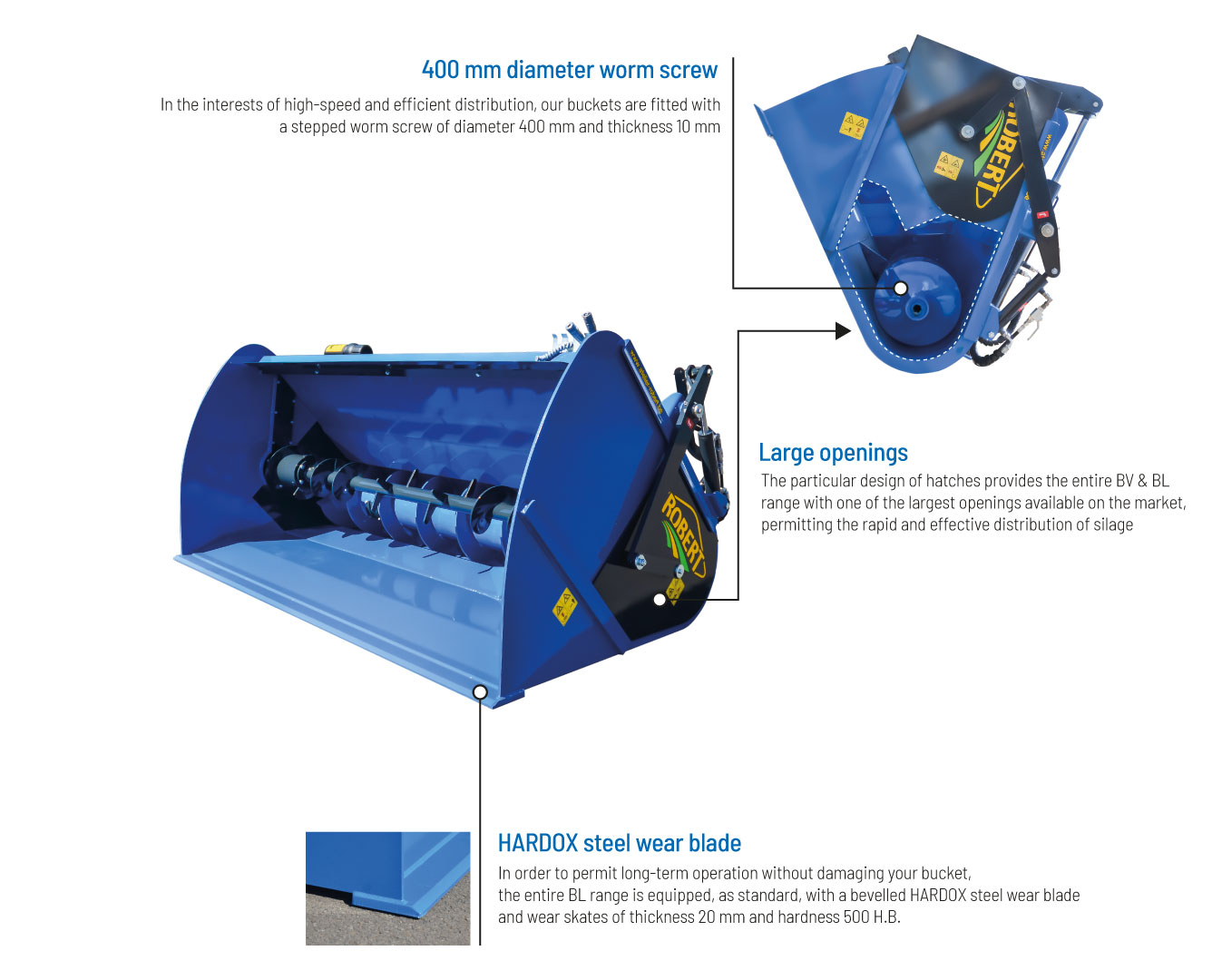

3 • 400 mm diameter worm screw

In the interests of high-speed and efficient distribution, our buckets are fitted with a stepped worm screw of diameter 400 mm and thickness 10 mm.

4 • HARDOX steel wear blade

In order to permit long-term operation without damaging your bucket, the entire BV range is equipped, as standard, with a bevelled HARDOX steel wear blade and wear skates of thickness 20 mm and hardness 500 H.B.

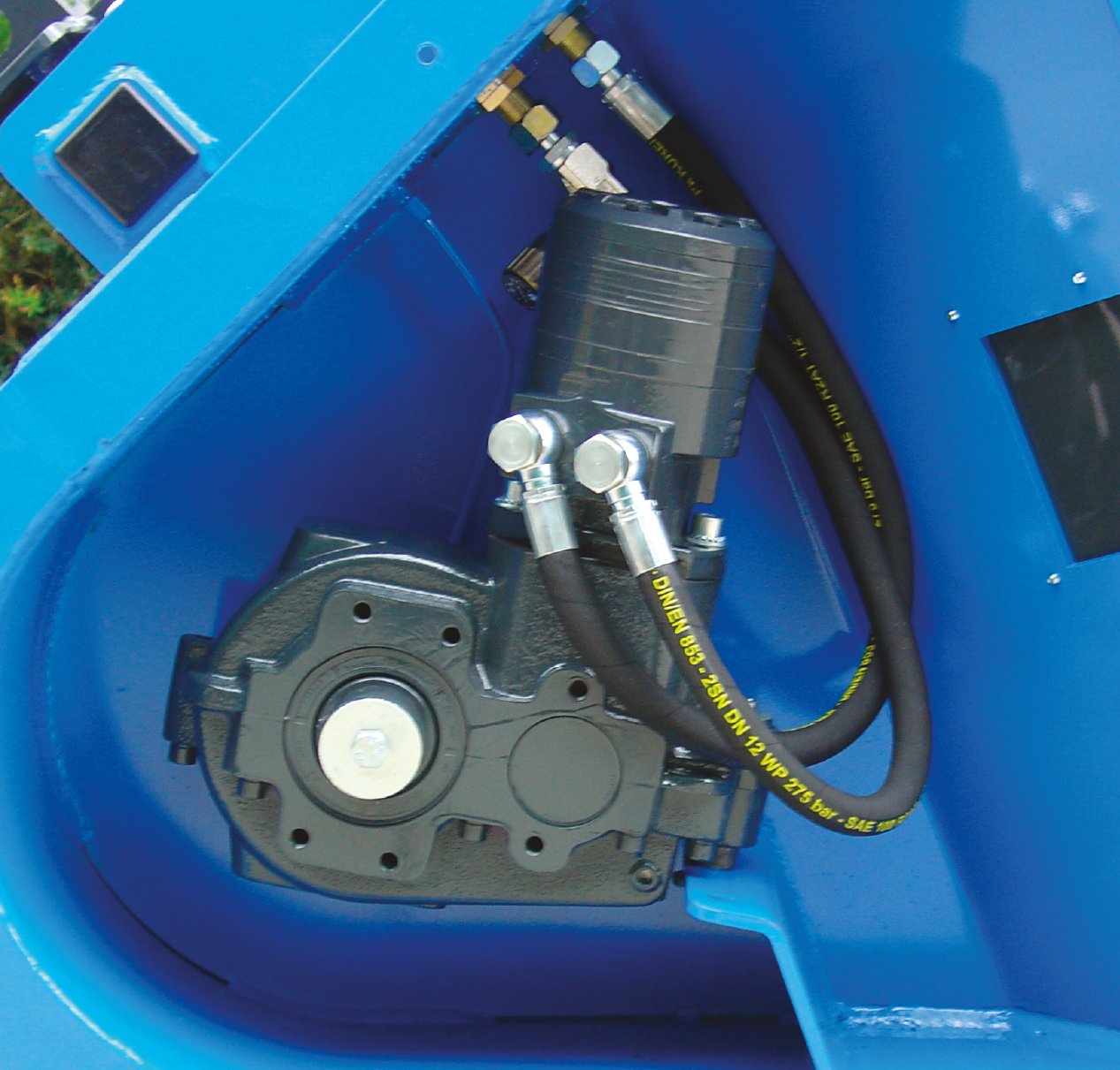

5 • Hydraulic motor

The screw conveyor is driven by a powerful hydraulic motor, via an oil-immersed gearbox.

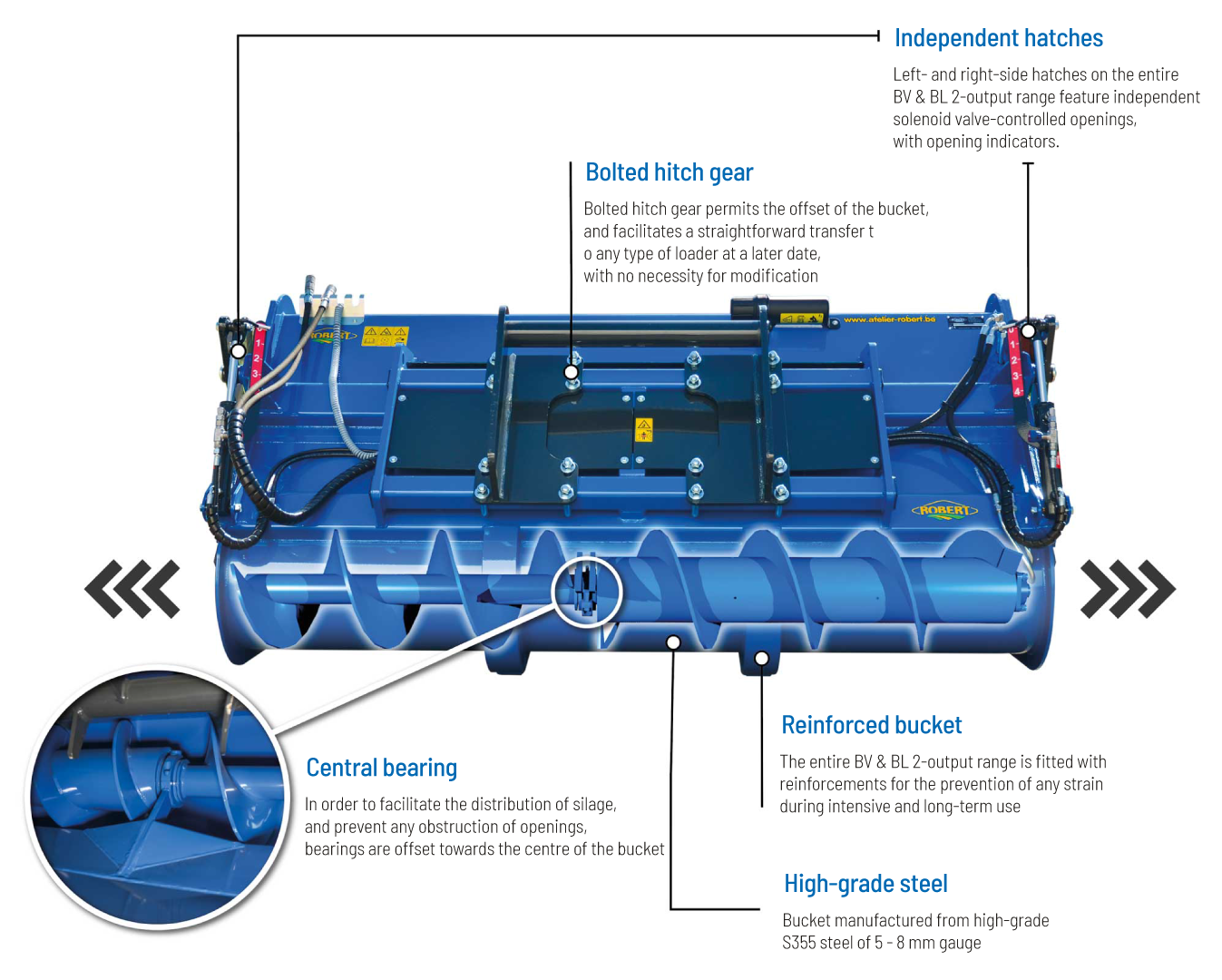

6 • Bolted hitch gear

Bolted hitch gear for the offset of the bucket and straightforward transfer to another type of loader at a later date, with no necessity for modification.

7 • Hydraulic actuator

Hatch opening by hydraulic actuator

8 • Hydraulic hatch

Hydraulic hatch interlocked with the movement of the screw, in order to ensure perfect leak-tightness during transport.

9 • Efficient distribution

Large output, combined with a 400 mm diameter screw, permits the rapid and efficient distribution of silage.

Even greater multi-functional capability provided by various silage feeder types.

Articulated silage unloading rotor

According to width: +/- 574 kg Impeccable cutting face

An impeccable cutting face is provided by the large diameter rotor, fitted with detachable blades arranged in a spiral pattern, mounted on two arms which are actuated by two actuators, with automatic lowering control.

Articulated arm and gripper

According to width: +/- 373 kg A clean cutting face

Greater flexibility delivered by the double-articulated arm and gripper with four actuators; this permits operation in an outthrust position, out of reach of silage stores; speed of operation is combined with cleanliness and an impeccable silage cutting face.

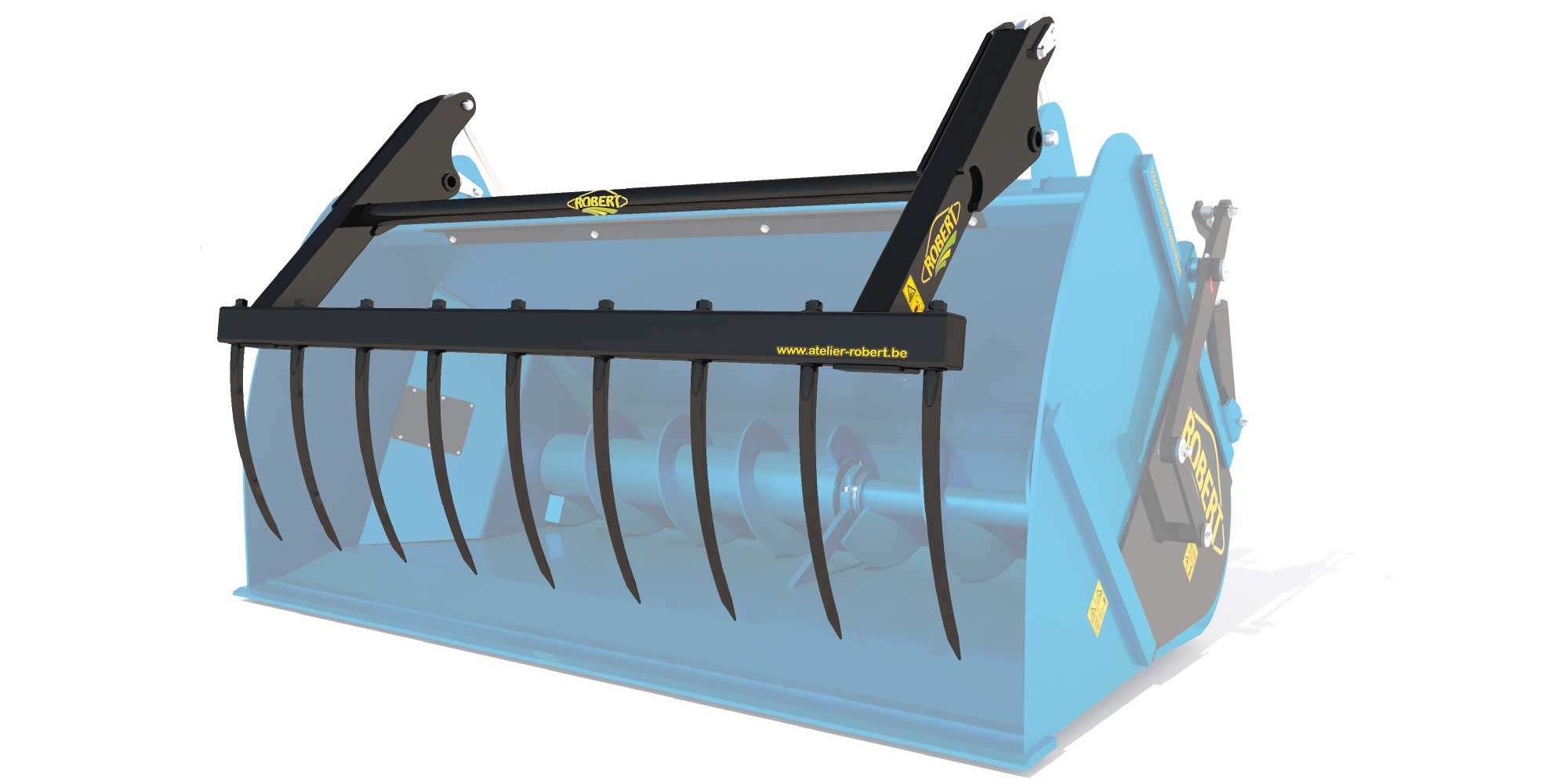

Crocodile silage feeder jaw

According to width: +/- 200 kg Multi-functional capability

The simplicity of this jaw permits silage feeding and the handling of straw bales or other bales.This jaw is equipped with detachable forged teeth and two actuators arranged on the exterior of the bucket, avoiding any contact with silage stores.

Silo Cut cutting jaw

According to width: +/- 574 kg Multi-functional capability

High-speed and impeccable cutting of silage delivered by a gate which is fitted with detachable blades and actuated by two powerful actuators, arranged on the exterior of the bucket.

Standard equipment

- High-resistance box

- Storied stepped diameter 400 mm thickness 10 mm with removable housing

- Auger driven by a gear motor

- Left side distribution / right side as an option

- Hydraulic unloading door connected with auger movement

- Wear blade 150 x 20 Hardox

- Removable coupling hooks

- Anti-corrosion treatment: epoxy primer and polyurethane finish

- Hitch included

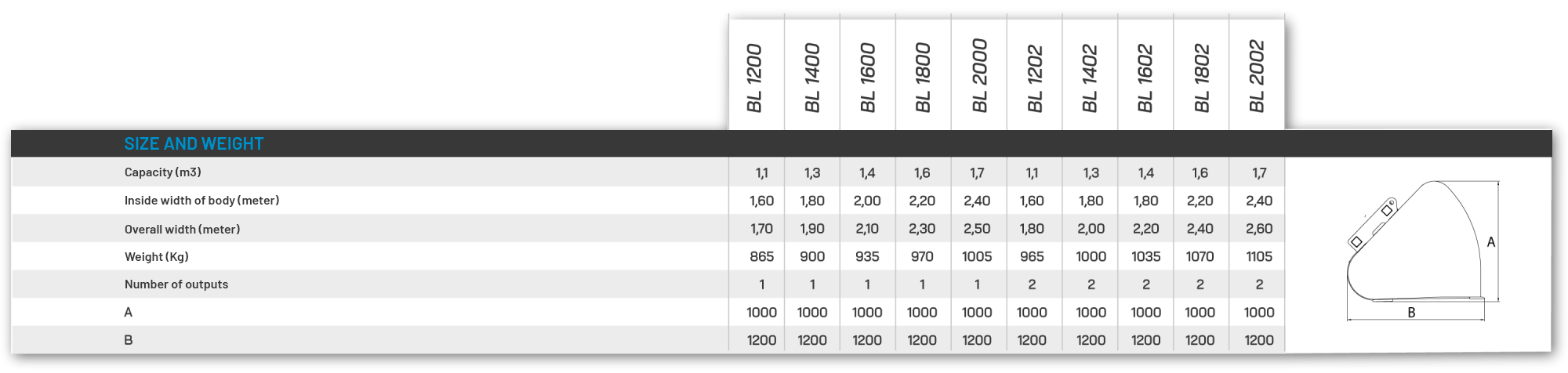

Features