Assets

DDT700 • 900: main assets

1 • Mechanical detanglers

The DDT700 and 900 are equipped with two mechanical bale separators for fast and efficient unravelling of all wrapped bales and for an even distribution.

2 • Hydraulic axle

For easy and clean loading of all types of silage, the axle is equipped with a hydraulic device to lower the box to ground level. A simple movement of the claw arm allows to load the goods with great ease.

3 • Claw arm

For precise loading without the use of an additional loader, the DDT700 and 900 are equipped with a double movement claw arm.

4 • Shrink plate on the claw teeth

To allow clean loading of silage at all levels, the claw is & equipped with a retractable plate on springs.

5 • Reinforced feeding belt

Conveyor belt with 80/12 flat chains and bolted slats in 80x40 mm for an efficient advance of the material in the detanglers.

![]()

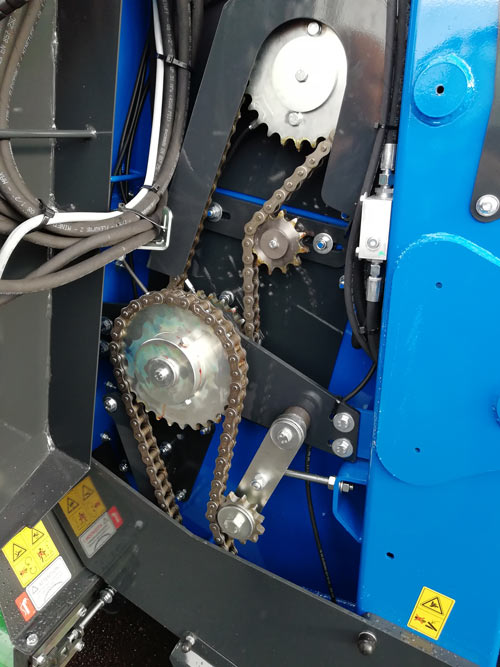

6 • Mechanical transmission of detanglers

Transmission of the shredders by chain and sprockets.

7 • Transmission of the second detangler

The transmission of the second shredder is made by mechanical system with chain and tensioner.

8 • Centralized lubrication

For the lubrication of the mechanical parts of your silo, the grease nipples are centralized in a place protected by a cover.

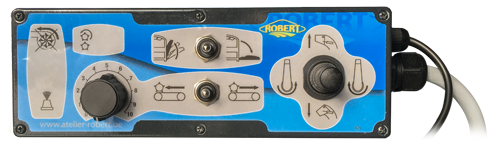

9 • Electric control box

The electric control box allows you to control all the elements of your straw blower individually from your cab.

10 • Belt tension

To adjust the belt tension, the tensioner is positioned outside the box. This makes the operation quick and easy.

11 • Cardan shaft with friction clutch

The cardan shaft with friction clutch and freewheel is standard on all our belt feeder silos.

12 • High power gear motorcycle

The belt is driven by a high power variable speed gear motor.

Standard equipment

- Conveyor driven by a variable speed motor reducer

- Conveyor with 80/12 flat chains and 80 x 40 bolted slats

- 2 mechanical shredders

- Left and right distribution belt in PVC

- Double sealing bottom and cleaning hatch

- Loading arm and claw with retractable sealing plate

- Hydraulic distributors with electric controls

- Manual and hydraulic brake

- Electric control box in cabin

- Drawbar with double drawbar

- Cardan shaft with friction safety and free wheel

- DDT 400 axle with 285-70 R 19.5 wheels

- DDT 700 - DDT 900 Axle with wheels 295-60 R22.5

- Road signs

- Anti-corrosion treatment: epoxy primer and polyurethane finish

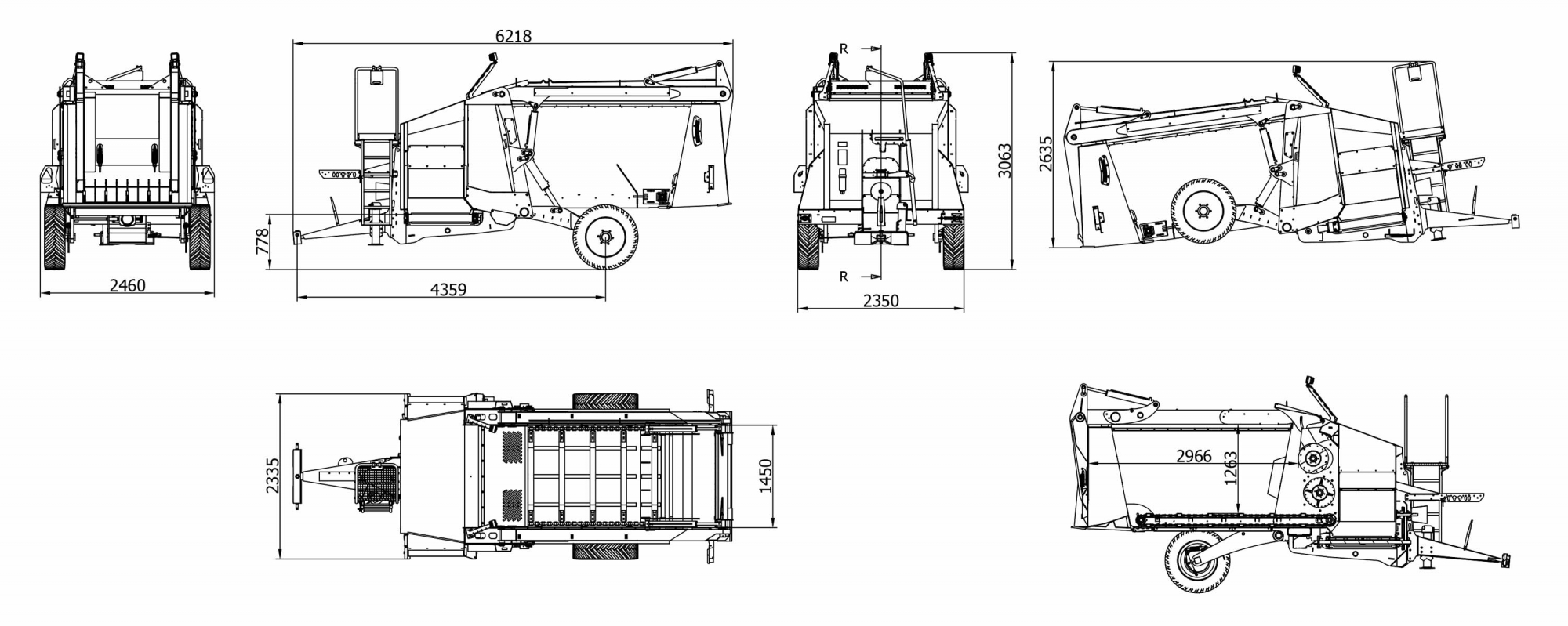

Features