Its advantages

The HYDROPAIL 2 Evo has been developed to meet in many points the criteria and requirements of breeders:

Reliability

Meticulous design and the use of high-quality hydraulic and mechanical components from globally renowned and recognized manufacturers elevate HYDROPAIL 2 EVO straw blowers to the level of the most reliable machines available on the market.

High capacity

Our super-powerful separators have undergone extensive tests in order to ensure that they meet the capacity requirements of stock farmers. By the combination of the separator with a high-efficiency turbine, the capacity of the HYDROPAIL 2 EVO straw blower is among the highest available on the market.

Ease of maintenance

HYDROPAIL 2 EVO straw blowers are designed for easy maintenance, due to the exceptional ease of access to conveyor belt tensioners and mechanical components. The turbine is equipped with an access hatch for the execution of all the necessary checks for its correct operation.

Exemplary robustness

Notre réputation s’est forgée à travers les années grâce à la qualité exemplaire et la robustesse de nos machines. L’HYDROPAIL2 EVO ne déroge pas à cette règle avec sa caisse monocoque indéformable.

Contrôle des flux

L’HYDROPAIL 2 EVO bénéficie depuis de nombreuses années de toutes les recherches réalisées par notre bureau d’étude sur le comportement des flux d’air et de matière. Par le parfait contrôle de ces flux, nous commercialisons l’un des meilleurs systèmes de paillage présent sur le marché.

Visibility

Due to its front-mounted position, which ensures the excellent visibility of manoeuvres, the HYDROPAIL 2 can reach the tightest spaces. Particular attention has been paid to ergonomics in the design of the HYDROPAIL 1, in order to provide the user with excellent visibility during straw blowing operations, whilst maintaining an unobstructed view of the environment in which they are moving.

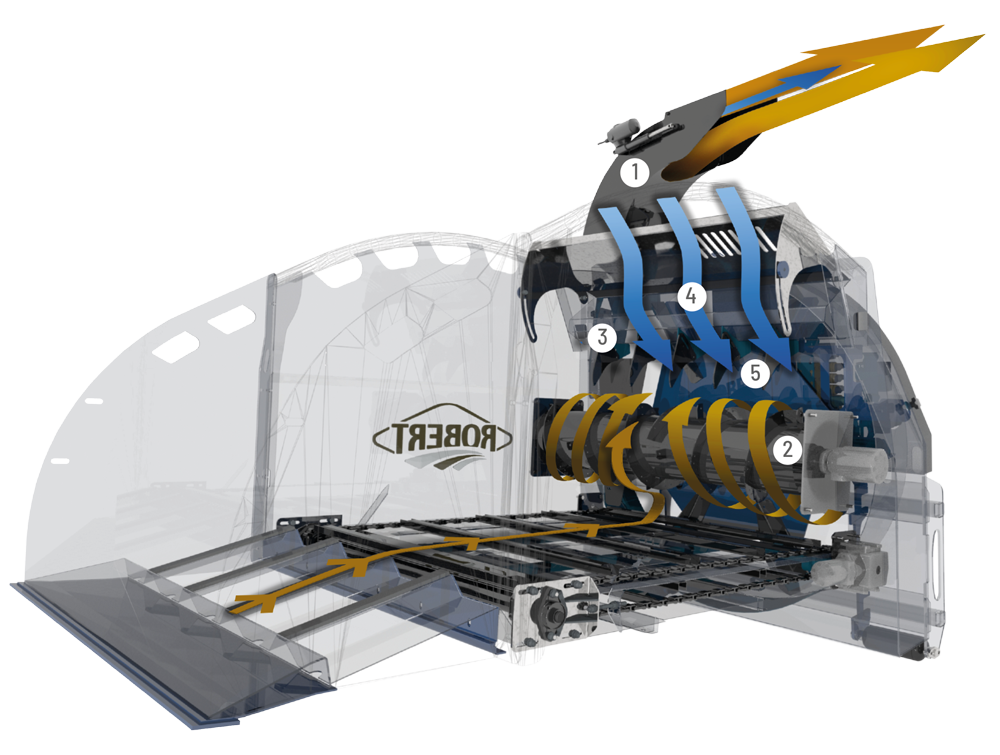

A combination of refined technical features for the achievement of optimum straw blowing.

3 - Regulator combs

As it is not possible to maintain a consistent quality of straw, the HYDROPAIL 1 has been designed for the full preservation of straw characteristics. The regulator combs permit the execution of the necessary adjustments.

4 - Controlled air intake

In order to achieve effective straw blowing, it must be possible to control the quantity and movement of air and straw in the turbine and the chute. Particular attention has been paid to this point, in order to achieve an exceptional result.

1 - Jet concentrator chute

In order to achieve a consistent straw blowing capacity at a specific location, it is important that the quantity of straw deposited should be clearly visible. In order to prevent any umbrella-shaped jet, the lateral and rotating chutes of the HYDROPAIL 2 EVO feature a geometry which has been specially designed to concentrate the straw into a powerful and compact jet. This improves the visibility of work executed, whilst producing a substantial reduction in the quantity of dust in suspension in the air.

2 - Spiral separators

For the execution of powerful separation, while generating a movement of straw which is conducive to its intake into the turbine, our hydraulically-driven separators feature a spiral design, and generate dynamic conditions which increase the quantity of straw delivered to the turbine. This particular design has proved its effectiveness for both round and square bales.

5 - Twin-flux turbine

The HYDROPAIL 2 EVO features a special and exceptionally quiet twin-flux ROBERT turbine of diameter 1 metre, with 6 bolted blades for maximum straw blowing efficiency.

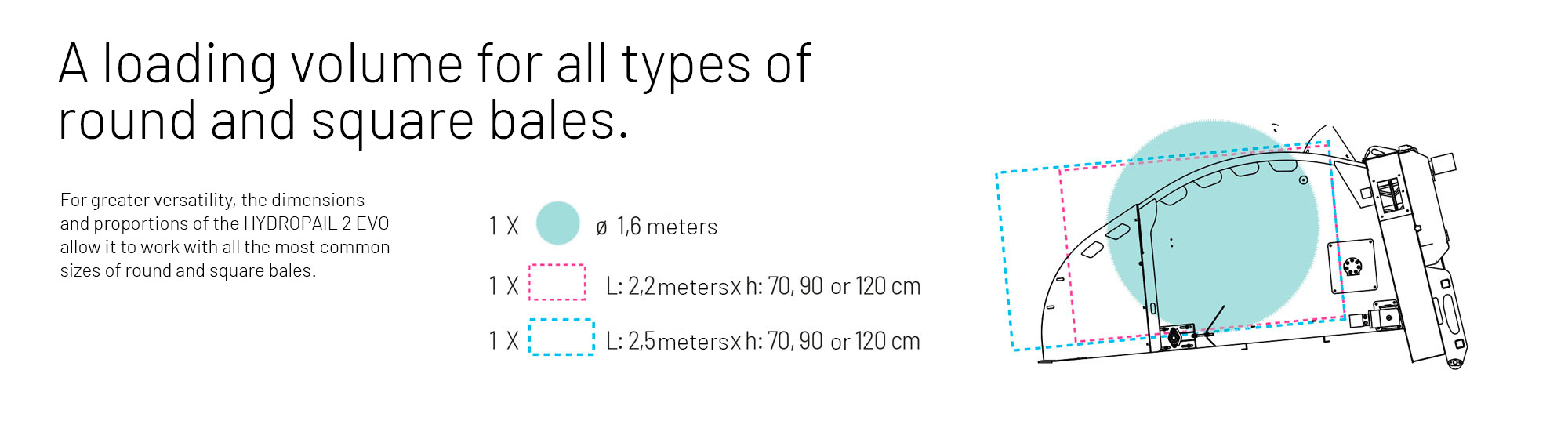

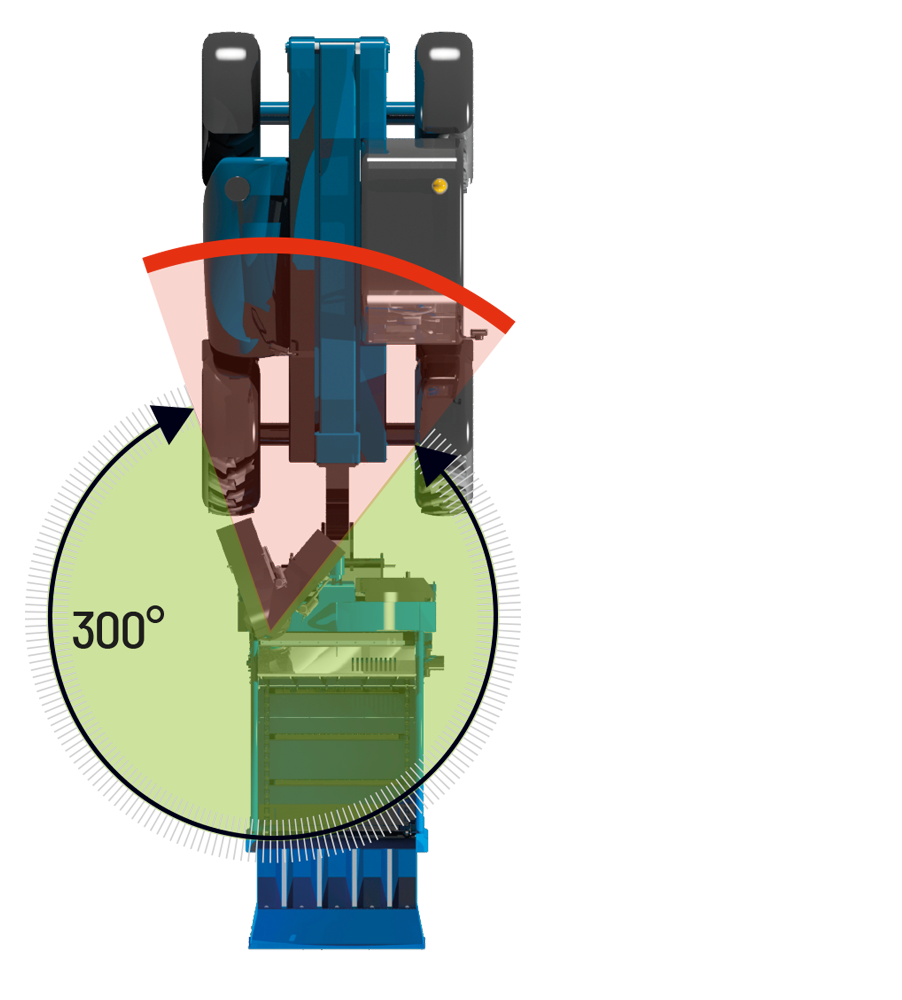

A rotating chute for completely safe straw blowing in the tightest corners

The rotating chute of the HYDROPAI 2 EVO has been specially designed to permit accurate straw blowing by any user, in any location required. Although it would have been possible to extend the operating radius of the chute, for safety reasons we have restricted this radius to 300 degrees, in order to protect the user from any projection in the direction of the control station.

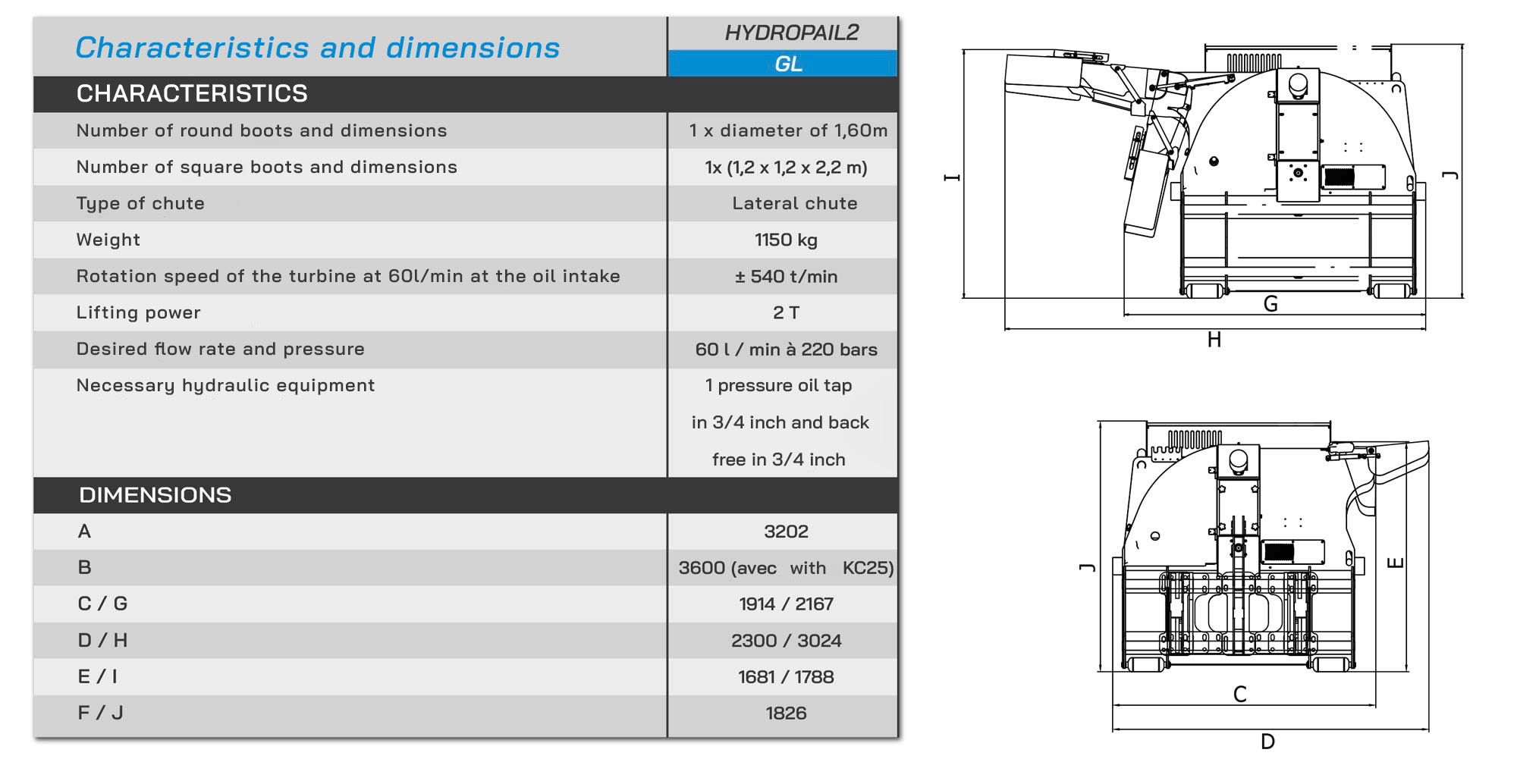

Standard equipment

- Conveyor driven by a variable-speed gear motor (manual variable drive control)

- Conveyor with flat 80/9 chains and 60 x 30 boards

- 1 hydraulic beater

- Regulating grabs

- 1.6 m bolted blade turbine

- Hydraulically driven turbine

- Lateral chute on the right - for GL models (optional GG)

- Rotating chute - for GT models

- Double bottom seal

- Hydraulic rear tailgate (only for COMPACT models)

- Electric control hydraulic distributors

- Electric control cabinet box (with deck and electric outlets)

- Removable coupling hooks

- Anti-corrosion treatment: epoxy primer and polyurethane finish

- Hitch included (type to be specified)

Features